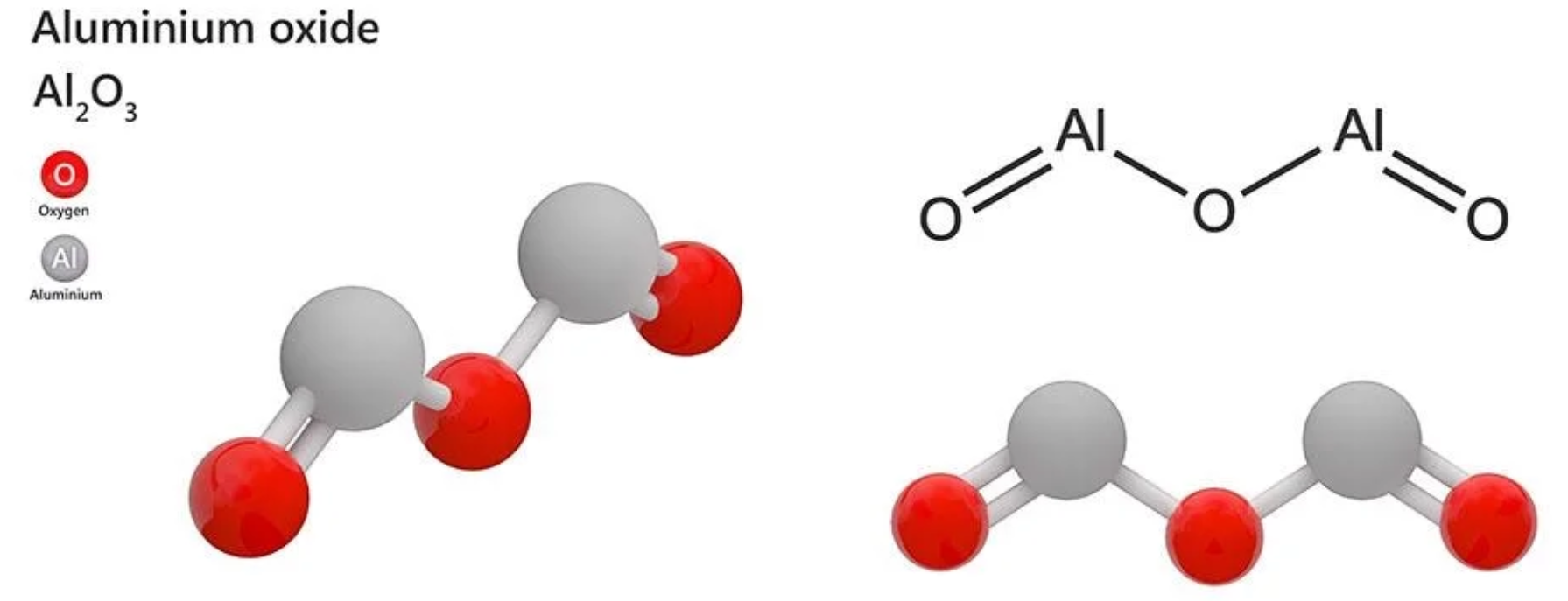

♦Alumina (Al)2O3)

Cov khoom siv ceramic precision uas tsim los ntawm ZhongHui Intelligent Manufacturing Group (ZHHIMG) tuaj yeem ua los ntawm cov khoom siv ceramic purity siab, 92 ~ 97% alumina, 99.5% alumina, >99.9% alumina, thiab CIP txias isostatic nias. Kev kub siab sintering thiab precision machining, qhov tseeb ntawm qhov ntev ntawm ± 0.001 hli, smoothness txog Ra0.1, siv kub txog 1600 degrees. Cov xim sib txawv ntawm ceramics tuaj yeem ua raws li cov neeg siv khoom xav tau, xws li: dub, dawb, beige, tsaus liab, thiab lwm yam. Cov khoom siv ceramic precision tsim los ntawm peb lub tuam txhab yog resistant rau kub siab, corrosion, hnav thiab rwb thaiv tsev, thiab tuaj yeem siv tau ntev hauv qhov kub siab, nqus tsev thiab corrosive roj ib puag ncig.

Siv dav hauv ntau yam khoom siv semiconductor: Frames (ceramic bracket), Substrate (base), Caj Npab / Choj (manipulator), , Mechanical Components thiab Ceramic Air Bearing.

| Lub Npe Khoom | Siab Purity 99 Alumina Ceramic Square Tube / Yeeb Nkab / Qws | |||||

| Cov Ntawv Qhia | Chav tsev | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Qhov Ceev | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Kev Nqus Dej | % | <0.1 | <0.1 | 0 | 0 | |

| Kub Sintered | ℃ | 1620 xyoo | 1650 xyoo | 1800 xyoo | 1800 xyoo | |

| Qhov nyuaj | Mohs | 7 | 9 | 9 | 9 | |

| Lub zog khoov (20 ℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Lub zog compressive | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Kub Ua Haujlwm Ntev | ℃ | 1350 xyoo | 1400 | 1600 xyoo | 1650 xyoo | |

| Kub Tshaj Plaws Ua Haujlwm | ℃ | 1450 xyoo | 1600 xyoo | 1800 xyoo | 1800 xyoo | |

| Ntim Resistivity | 20 ℃ | Ω. cm3 | >1013 | >1013 | >1013 | >1013 |

| 100 ℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300 ℃ | >109 | >1010 | >1012 | >1012 | ||

Daim ntawv thov ntawm cov khoom siv alumina siab purity:

1. Siv rau cov khoom siv semiconductor: ceramic nqus tsev chuck, txiav disc, ntxuav disc, ceramic CHUCK.

2. Cov khoom hloov pauv wafer: wafer tuav chucks, wafer txiav discs, wafer ntxuav discs, wafer optical tshuaj xyuas suction khob.

3. LED / LCD vaj huam sib luag tiaj tus zaub kev lag luam: ceramic nozzle, ceramic sib tsoo disc, LIFT PIN, PIN rail.

4. Kev sib txuas lus kho qhov muag, kev lag luam hnub ci: cov kav dej ceramic, cov pas nrig ceramic, lub rooj tsavxwm luam ntawv ceramic scrapers.

5. Cov khoom uas tiv taus cua sov thiab hluav taws xob rwb thaiv tsev: cov kabmob ceramic.

Tam sim no, cov khoom siv aluminium oxide ceramics muaj peev xwm muab faib ua cov khoom siv ceramic uas muaj cov khoom siv purity siab thiab cov khoom siv ceramic feem ntau. Cov khoom siv ceramic uas muaj cov khoom siv aluminium oxide siab yog cov khoom siv ceramic uas muaj Al₂O₃ ntau tshaj 99.9%. Vim nws qhov kub sintering txog li 1650 - 1990 ° C thiab nws qhov wavelength kis tau ntawm 1 ~ 6μm, nws feem ntau yog ua tiav rau hauv iav fused es tsis yog platinum crucible: uas tuaj yeem siv ua sodium tube vim nws lub teeb transmittance thiab corrosion tsis kam rau alkali hlau. Hauv kev lag luam hluav taws xob, nws tuaj yeem siv ua cov khoom siv rwb thaiv tsev siab rau IC substrates. Raws li cov ntsiab lus sib txawv ntawm aluminium oxide, cov khoom siv aluminium oxide ceramic feem ntau tuaj yeem muab faib ua 99 ceramics, 95 ceramics, 90 ceramics thiab 85 ceramics. Qee zaum, cov khoom siv ceramic uas muaj 80% lossis 75% ntawm aluminium oxide kuj raug cais ua cov khoom siv aluminium oxide ceramic feem ntau. Ntawm lawv, 99 txhuas oxide ceramic khoom siv yog siv los tsim cov crucible kub siab, hluav taws kub lub raj cua sov thiab cov khoom siv tshwj xeeb uas tsis yooj yim hnav, xws li cov bearings ceramic, ceramic seals thiab valve plates. 95 txhuas ceramics feem ntau yog siv ua qhov chaw tiv taus corrosion. 85 ceramics feem ntau sib xyaw ua ke hauv qee yam khoom, yog li txhim kho kev ua haujlwm hluav taws xob thiab lub zog kho tshuab. Nws tuaj yeem siv molybdenum, niobium, tantalum thiab lwm yam hlau seals, thiab qee qhov siv ua cov khoom siv hluav taws xob nqus tsev.

| Khoom Zoo (Tus Nqi Sawv Cev) | Lub Npe Khoom | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Cov Khoom Siv Tshuaj Lom Zem Uas Muaj Sodium Tsawg | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Lol | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Qhov Nruab Nrab Particle Diameter (MT-3300, txoj kev tshuaj xyuas laser) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| α Qhov Loj Crystal | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Kev Ua Kom Ceev** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Qhov Ceev ntawm Sintering** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Tus Nqi Ntsws Ntawm Kab Sintering ** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO tsis suav nrog rau hauv kev suav qhov huv ntawm Al₂O₃.

* Tsis muaj hmoov scaling 29.4MPa (300kg / cm²), qhov kub sintering yog 1600 ° C.

AES-11 / 11C / 11F: Ntxiv 0.05 ~ 0.1% MgO, qhov sinterability zoo heev, yog li nws siv tau rau txhuas oxide ceramics nrog qhov huv ntawm ntau dua 99%.

AES-22S: Tus yam ntxwv los ntawm kev ua kom siab thiab qhov nrawm qis ntawm cov kab sintering, nws siv tau rau kev ua cov ntawv nplaum thiab lwm yam khoom loj nrog qhov tseeb ntawm qhov ntev.

AES-23 / AES-31-03: Nws muaj qhov ceev dua, thixotropy thiab viscosity qis dua li AES-22S. tus qub yog siv rau ceramics thaum tus tom kawg yog siv los ua dej reducer rau cov ntaub ntawv fireproofing, tau txais kev nyiam.

♦ Cov yam ntxwv ntawm Silicon Carbide (SiC)

| Cov Yam Ntxwv Dav Dav | Qhov huv ntawm cov khoom tseem ceeb (wt%) | 97 | |

| Xim | Dub | ||

| Qhov Ceev (g/cm³) | 3.1 | ||

| Kev nqus dej (%) | 0 | ||

| Cov Yam Ntxim Saib Xyuas Tshuab | Lub zog khoov (MPa) | 400 | |

| Cov qauv hluas (GPa) | 400 | ||

| Vickers hardness (GPa) | 20 | ||

| Cov yam ntxwv ntawm thermal | Qhov kub siab tshaj plaws ua haujlwm (°C) | 1600 xyoo | |

| Cov coefficient ntawm kev nthuav dav thermal | RT ~ 500 ° C | 3.9 | |

| (1/°C x 10-6) | RT ~ 800 ° C | 4.3 | |

| Kev ua kom sov (W/m x K) | 130 110 | ||

| Kev tiv thaiv thermal poob siab ΔT (°C) | 300 | ||

| Cov yam ntxwv hluav taws xob | Ntim resistivity | 25°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectric tas mus li | 10GHz | - | |

| Kev poob dielectric (x 10-4) | - | ||

| Q Factor (x 104) | - | ||

| Lub zog hluav taws xob dielectric tawg (KV / hli) | - | ||

♦Silicon Nitride Tej Hub

| Khoom siv | Chav tsev | Si₃N₄ |

| Txoj Kev Sintering | - | Roj Siab Sintered |

| Qhov Ceev | g/cm³ | 3.22 |

| Xim | - | Xim av tsaus |

| Tus Nqi Nqus Dej | % | 0 |

| Cov Hluas Modulus | Gpa | 290 |

| Vickers Hardness | Gpa | 18 - 20 |

| Lub zog compressive | Mpa | 2200 |

| Lub zog khoov | Mpa | 650 |

| Kev Ua Kub | W/mK | 25 |

| Kev Tiv Thaiv Kev Kub Ntxhov | Δ (°C) | 450 - 650 |

| Kub Tshaj Plaws Ua Haujlwm | °C | 1200 |

| Ntim Resistivity | Ω·cm | > 10 ^ 14 |

| Dielectric tas mus li | - | 8.2 |

| Lub zog dielectric | kV/hli | 16 |