Hauv cov chav ntsiag to ntawm cov chaw kuaj ntsuas, cov chav ntxuav semiconductor, thiab cov chaw ntsuas aerospace, muaj kev hloov pauv ntsiag to. Nws tsis yog tsav los ntawm software lossis sensors ib leeg xwb - tab sis los ntawm cov ntaub ntawv uas tsim lub hauv paus ntawm kev ntsuas nws tus kheej. Nyob rau pem hauv ntej ntawm qhov kev hloov pauv no yog cov cuab yeej ntsuas ceramic siab heev, suav nrog lub ultra-stable ceramic air straight ruler thiab lub exceptionally rigid high precision silicon-carbide (Si-SiC) parallelepiped thiab square. Cov no tsis yog cov cuab yeej xwb; lawv yog cov neeg ua haujlwm ntawm lub sijhawm tshiab uas kev ruaj khov, rov ua dua, thiab thermal neutrality tsis tuaj yeem sib tham tau.

Tau ntau tshaj ib nrab xyoo pua, granite dub tau tswj hwm qhov kev ntsuas qhov tseeb. Nws qhov kev ua kom noo noo ntuj, kev nthuav dav thermal qis, thiab qhov tiaj tiaj zoo heev ua rau nws yog cov khoom siv rau cov phaj nto, cov plaub fab, thiab cov npoo ncaj. Txawm li cas los xij, thaum cov lag luam thawb mus rau hauv sub-micron thiab txawm tias nanometer-scale tolerances - tshwj xeeb tshaj yog hauv semiconductor lithography, space optics, thiab quantum computing - granite cov kev txwv tau pom tseeb ntau dua. Nws hnyav, yooj yim rau micro-chipping nyob rau hauv kev sib cuag ntau zaus, thiab, txawm tias nws lub koob npe nrov, tseem qhia txog me ntsis ntev creep nyob rau hauv load lossis ib puag ncig hloov pauv.

Nkag mus rau hauv cov khoom siv ua los ntawm ...

Piv txwv li, siv lub tshuab ntsuas cua ceramic. Tsim los siv nrog cov theem cua lossis cov optical interferometers, cov cuab yeej no xav tau qhov ncaj nraim zoo meej, qhov hnyav tsawg kawg nkaus, thiab tsis muaj qhov hloov pauv thermal.cov kav dej ua los ntawm cov av nplaum—ua kom tiaj tiaj thiab ncaj nraim hauv ±0.5 µm dhau 500 hli thiab txhuam kom du rau qhov roughness ntawm qhov chaw hauv qab Ra 0.02 µm—ua tau raws li qhov ntawd. Lawv qhov ceev qis (~3.6 g/cm³) txo qhov inertia hauv cov txheej txheem ntsuas dynamic, thaum lawv qhov tsis yog hlau nplaum, tsis yog conductive tshem tawm kev cuam tshuam hauv cov khoom siv hluav taws xob lossis hlau nplaum rhiab heev. Hauv cov cuab yeej tshuaj xyuas wafer lossis cov teeb tsa calibration laser tracker, qhov twg txawm tias ib lub micron ntawm hneev tuaj yeem ua rau cov txiaj ntsig tsis sib xws, tus kav cua ceramic muab qhov ruaj khov, inert reference uas tseem muaj tseeb thoob plaws qhov kub thiab txias thiab kev ua haujlwm voj voog.

Tab sis thaum xav tau qhov ruaj khov thiab thermal conductivity kawg - xws li hauv qhov chaw tsom iav tsom iav lossis lub zog laser cavity metrology - cov engineers tig mus rau qhov tseeb siab silicon-carbide (Si-SiC) parallelepiped thiab square Cheebtsam. Si-SiC yog cov ntaub ntawv ruaj khov tshaj plaws paub, nrog Young's modulus tshaj 400 GPa - ntau dua peb zaug ntawm hlau - thiab thermal conductivity sib tw nrog txhuas. Qhov tseem ceeb, nws cov coefficient ntawm thermal expansion (CTE) tuaj yeem tsim los phim cov iav optical lossis silicon wafers, ua rau ze li xoom qhov sib txawv nthuav dav hauv hybrid sib dhos. Lub Si-SiC square siv ua tus tswv siv hauv EUV lithography cuab yeej yuav tsis tsuas yog tuav nws daim ntawv - nws yuav tiv taus kev cuam tshuam los ntawm kev cua sov hauv zos lossis kev co.

Qhov ua rau cov kev ua tiav no ua tau tsis yog tsuas yog cov khoom siv xwb, tab sis kuj yog kev paub txog kev tsim cov cuab yeej ntsuas ceramic. Piv txwv li, kev ua kom raug ntawm Si-SiC xav tau cov log sib tsoo pob zeb diamond, cov platform CNC sub-micron, thiab cov txheej txheem lapping ntau theem ua nyob rau hauv qhov chaw tswj qhov kub thiab txias. Txawm tias qhov kev ntxhov siab me me los ntawm kev sintering tsis raug tuaj yeem ua rau muaj kev puas tsuaj tom qab kev ua haujlwm. Yog vim li cas tsuas yog ob peb lub tuam txhab tsim khoom thoob ntiaj teb thiaj li koom ua ke cov khoom siv sib xyaw, kev tsim khoom meej, thiab kev ntsuas kawg hauv ib lub ru tsev - lub peev xwm uas cais cov neeg tsim khoom ntsuas tiag tiag los ntawm cov neeg muag khoom ceramic dav dav.

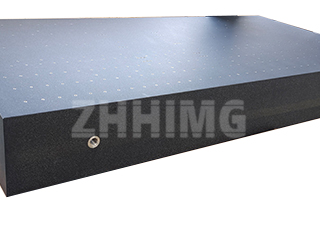

Ntawm ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG), qhov kev sib koom ua ke no yog qhov tseem ceeb rau peb lub hom phiaj. Peb cov cuab yeej ntsuas ceramic—xws li cov qauv kav hlau ceramic cua ncaj nraim uas tau ntawv pov thawj rau DIN 874 Qib AA thiab cov khoom siv siab precision silicon-carbide (Si-Si-C) parallelepiped thiab cov khoom siv square uas taug qab tau raws li PTB thiab NIST cov qauv—yog tsim tawm hauv ISO Class 7 chav huv siv cov txheej txheem sintering thiab tiav. Txhua yam khoom siv dhau los ntawm kev lees paub tag nrho interferometric, CMM kev lees paub ntawm geometric tolerances (flatness, parallelism, perpendicularity), thiab kev sim kev ncaj ncees ntawm qhov chaw ua ntej xa khoom. Qhov tshwm sim yog cov khoom siv qib siv uas tsis yog ua tau raws li cov lus qhia xwb—nws tshaj lawv tas li thoob plaws cov pawg.

Qhov kev thov rau kev ua tau zoo li no tab tom nce siab. Hauv kev tsim khoom semiconductor, EUV thiab cov tshuab lithography siab-NA xav tau cov qauv sib dhos ruaj khov rau hauv kaum tawm nanometers dhau qhov deb ntawm lub 'meter' - tsis yooj yim sua yam tsis muaj Si-SiC's thermal-mechanical synergy. Hauv kev tsav dav hlau, cov rooj zaum kho qhov muag satellite ua los ntawm cov khoom siv ceramic ua kom muaj kev ruaj khov ntawm lub voj voog txawm tias muaj kev hloov pauv kub heev. Txawm tias nyob rau hauv cov teb tshiab xws li kev tshawb pom nthwv dej gravitational lossis kev tsim kho moos atomic, qhov twg picometer-level stability tseem ceeb, cov khoom siv ceramic thiab Si-SiC metrology artifacts tau dhau los ua qhov tseem ceeb.

Qhov tseem ceeb, cov cuab yeej no kuj hais txog kev ruaj khov thiab tag nrho cov nqi ntawm kev muaj. Txawm hais tias kev nqis peev thawj zaug hauv cov khoom siv siab precision silicon-carbide parallelepiped yuav ntau dua li ntawm cov granite sib npaug, nws lub neej kev pabcuam tuaj yeem ntev dua 5-10 npaug hauv cov chaw siv siab. Nws tsis tas yuav siv roj, tiv taus txhua yam cov kuab tshuaj thiab plasmas, thiab yeej tsis xav tau kev kho dua tshiab vim yog kev nqus dej noo - tsis zoo li cov hlau cam khwb cia lossis txawm tias qee cov granites. Rau cov thawj tswj hwm zoo ua haujlwm raws li AS9100, ISO 13485, lossis SEMI cov qauv, qhov kev ntseeg siab no txhais tau ncaj qha mus rau hauv kev txo qis downtime, tsawg dua kev tshawb pom kev tshuaj xyuas, thiab kev ntseeg siab ntawm cov neeg siv khoom ntau dua.

Ntxiv mus, qhov zoo nkauj thiab kev ua haujlwm zoo nkauj ntawm cov cuab yeej no yuav tsum tsis txhob raug saib tsis taus. Lub xwmfab Si-SiC ci ntsa iab nrog lub teeb ci ntsa iab tab sis hnyav dua li hlau. Lub kav cua ceramic zoo li ruaj khov tab sis nqa tau yooj yim - zoo tagnrho rau kev txheeb xyuas tes hauv qhov chaw nqaim. Cov yam ntxwv no tseem ceeb hauv cov chaw kuaj mob tiag tiag uas ergonomics thiab yooj yim siv cuam tshuam rau kev ua haujlwm txhua hnub.

Yog li, cov cuab yeej ntsuas ceramic puas txhais dua qhov tseeb siab heev? Cov lus teb nyob hauv cov ntaub ntawv - thiab hauv daim ntawv teev cov thawj coj thoob ntiaj teb uas tam sim no teev lawv ua tus qauv. Los ntawm cov koom haum ntsuas hauv tebchaws uas lees paub cov qauv ntev tiam tom ntej mus rau Tier 1 cov neeg muab khoom lees paub cov khoom siv EV drivetrain, qhov kev hloov pauv yog qhov tseeb: thaum qhov tsis paub meej yuav tsum tau txo qis, cov engineers ntseeg cov engineered ceramics.

Thiab thaum cov lag luam txuas ntxiv mus rau kev tswj hwm qhov ntsuas atomic, ib qho tseeb tsis lees paub: yav tom ntej ntawm kev ntsuas yuav tsis raug txiav los ntawm pob zeb lossis pov rau hauv hlau. Nws yuav raug sintered, sib tsoo, thiab polished hauv ceramic - thiab silicon carbide.

ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (ZHHIMG) yog ib lub tuam txhab tsim khoom thoob ntiaj teb uas paub zoo txog kev daws teeb meem ultra-precision ceramic thiab silicon-carbide metrology. Tshwj xeeb hauv kev ntsuas ceramic, ceramic air straight ruler, thiab high precision silicon-carbide (Si-SiC) parallelepiped thiab square components, ZHHIMG xa cov khoom siv kuaj mob uas tau ntawv pov thawj tag nrho rau semiconductor, aerospace, kev tiv thaiv, thiab kev tshawb fawb. Muaj daim ntawv pov thawj ISO 9001, ISO 14001, thiab CE, peb cov khoom tau txais kev ntseeg siab los ntawm cov tuam txhab thev naus laus zis thoob ntiaj teb. Tshawb nrhiav peb cov khoom siv metrology siab heev ntawmwww.zhhimg.com.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-05-2025