Hauv kev nrhiav tsis tu ncua ntawm cov microchips me dua, sai dua, thiab muaj zog dua, qhov kev thov tso rau ntawm Wafer Processing Equipment tab tom nce mus rau qib ntawm qhov tseeb uas yav dhau los suav tias tsis tuaj yeem ua tiav. Raws li cov yam ntxwv me me mus rau hauv ib tus lej nanometer realm, qhov ruaj khov ntawm tag nrho cov platform tsim khoom dhau los ua qhov tseem ceeb. Nws yog nyob ntawm no, hauv qab cov khoom siv lasers, lub tshuab nqus tsev, thiab cov tshuab robotic, uas cov khoom siv ntawm keeb kwm thaum ub - granite ntuj - tshwm sim ua qhov txiav txim siab rau kev vam meej semiconductor niaj hnub no. Cov lus qhia tshwj xeeb, kev tsim kho, thiab kev muab cov khoom siv granite OEM siab thiab lub tshuab monolithic OEM granite tsis yog tsuas yog cov kev cai xwb; lawv yog lub hauv paus ntawm kev ua haujlwm ncaj ncees.

Lub luag haujlwm ntawm lub hauv paus tshuab hauv txhua lub kaw lus siab-precision yog los muab lub dav hlau siv ruaj khov thiab ruaj khov. Hauv qhov chaw tsis ruaj khov thiab qhov tseeb-qhov tseem ceeb ntawm kev tsim khoom semiconductor, qhov twg cov txheej txheem zoo li lithography, etching, thiab deposition tshwm sim, qhov sib txawv me me - txawm tias nyob rau theem sub-micron - tuaj yeem ua rau muaj kev poob qis loj heev. Kev xaiv cov khoom siv rau cov ntsiab lus tseem ceeb, xws li Wafer Processing Equipment tshuab hauv paus, yog li ntawd yog ib kauj ruam tsis sib tham hauv kev tsim qauv.

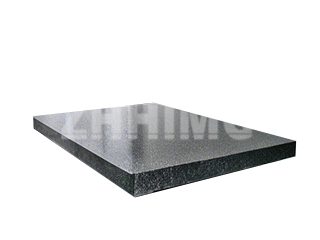

Cov txiaj ntsig zoo ntawm Natural Granite

Vim li cas cov pob zeb granite ntuj tsim thiaj ua tau zoo dua li cov khoom siv tsim xws li hlau cam khwb cia, hlau, lossis qee yam khoom sib xyaw hauv daim ntawv thov tshwj xeeb no? Cov lus teb yog nyob rau hauv nws cov khoom tshwj xeeb, laus ntuj tsim uas zoo meej rau qhov chaw tsis zam txim ntawm cov tshuab precision.

1. Kev Tiv Thaiv Kev Cob Qhia Zoo Tshaj Plaws (Kev Cais Tawm Ntawm Cov Txheej Txheem Dynamics):

Kev co yog qhov ua rau muaj kev tsim khoom nanoscale. Txawm tias tsim los ntawm sab hauv los ntawm cov motors thiab cov khoom txav mus los lossis sab nraud los ntawm hauv pem teb chav huv, txhua qhov kev co yuav tsum tau nqus sai. Granite muaj cov coefficient damping sab hauv siab - zoo dua li cov hlau. Cov khoom no txhais tau tias lub zog kho tshuab tau sai sai dissipated ua cua sov, tiv thaiv resonance thiab xyuas kom meej tias cov txheej txheem tseem ceeb tau ua tiav ntawm lub platform ruaj khov tiag tiag. Qhov no yog qhov tseem ceeb rau kev tswj hwm qhov chaw tseem ceeb hauv kev ua lithography siab heev lossis xyuas kom meej tias cov khoom siv tshem tawm thaum lub sijhawm tshuaj lom neeg kho tshuab planarization (CMP).

2. Kev Nthuav Dav Kub Ze Li xoom (Tswj Kev Sib Haum Xeeb):

Cov Khoom Siv Ua Wafer feem ntau cuam tshuam nrog qhov kub thiab txias hloov pauv, ob qho tib si ambient thiab cov txheej txheem ua rau. Cov ntaub ntawv hlau nthuav dav thiab cog lus ntau nrog rau qhov kub thiab txias hloov pauv, ua rau thermal drift thiab misalignment ntawm optical lossis mechanical systems. Granite, tshwj xeeb tshaj yog dub granite, qhia txog qhov coefficient qis heev ntawm thermal expansion (CTE), kwv yees li 3 × 10⁻⁶ / ℃. Qhov kev ruaj khov thermal no ua kom ntseeg tau tias qhov tseeb ntawm qhov ntev ntawm lub tshuab granite txaj thiab lwm yam OEM granite Cheebtsam tseem sib xws, txo qis qhov yuam kev thermal thiab lav qhov kev ntsuas rov ua dua nyob rau hauv ntau yam mob.

3. Qhov Kawg Flatness thiab Stiffness:

Los ntawm kev siv cov txheej txheem lapping thiab polishing siab heev, cov granite ntuj tuaj yeem ua tiav qhov chaw tiaj tiaj uas ntsuas hauv sub-microns - qhov tseem ceeb rau cov chaw siv hauv kev tswj kev txav mus los. Ntxiv mus, nws cov Young's modulus siab muab qhov zoo tshaj plaws static thiab dynamic stiffness. Qhov kev tiv thaiv no rau deflection hauv qab load yog qhov tseem ceeb, vim tias lub hauv paus yuav tsum txhawb nqa cov motors loj loj, theem, thiab cov qauv sib dhos Wafer Processing Equipment nyuaj yam tsis muaj kev hloov pauv ntsuas tau, txawm tias hla qhov loj.

Kev Tsim Kho Yav Tom Ntej: OEM Granite Cheebtsam thiab Kev Sib Dhos Ua Ke

Kev siv granite niaj hnub no nthuav dav tshaj li cov phaj nto yooj yim. Cov chaw tsim khoom siv thev naus laus zis niaj hnub no xav tau cov khoom siv granite OEM uas nyuaj, tsim tshwj xeeb. Cov no tuaj yeem suav nrog cov hlau qhia kev coj ua cua, cov chucks nqus tsev uas nyuaj, cov khoom theem ntau-axis, thiab cov thaiv mounting rau lasers thiab optics. Cov khoom no feem ntau yog machined nrog cov yam ntxwv geometric nyuaj, suav nrog cov qhov drilled rau wire routing, threaded inserts rau mounting, thiab precision machined dovetails lossis slots rau bearing systems.

Cov txheej txheem ntawm kev tsim cov khoom siv ua tiav Wafer pib nrog lub txaj tshuab granite loj. Cov khoom siv granite tom qab ntawd tau sib txuas lossis txuas nrog nws siv cov tshuaj epoxy-based, ib kauj ruam tseem ceeb uas ua kom tag nrho cov qauv ua haujlwm ua ib chav tsev, sib xws. Kev koom ua ke zoo xav tau kev saib xyuas kom meej:

-

Kev Kho Kom Haum: Cov khoom yuav tsum tau tsim ua raws li cov lus qhia tshwj xeeb ntawm cov neeg siv khoom, feem ntau suav nrog kev koom ua ke ntawm cov khoom tsis yog granite xws li cov kab txias thiab cov sensor mounts ncaj qha rau hauv cov qauv.

-

Kev Ruaj Ntseg Zoo: Txhua yam khoom yuav tsum tau tswj xyuas zoo, suav nrog kev txheeb xyuas qhov tiaj tus, qhov ncaj, thiab qhov sib npaug siv CMMs thiab laser interferometers, kom ntseeg tau tias lawv ua tau raws li ISO thiab cov qauv thoob ntiaj teb rau kev ntsuas thiab kev raug.

-

Kev Koom Tes Ua Lag Luam: Kev xaiv tus neeg muag khoom OEM granite yog kev koom tes. Nws yuav tsum muaj kev nkag siab tob txog daim ntawv thov semiconductor, lub peev xwm xaiv cov pob zeb raw qib siab tshaj plaws, thiab lub peev xwm tsim khoom los tshuab thiab sib sau ua ke cov qauv nyuaj rau nanometer tolerances.

Xaus lus, thaum lub microchip tiav lawm yog qhov txuj ci tseem ceeb ntawm tib neeg lub tswv yim, nws txoj kev tsim kho yog nyob ntawm qhov ruaj khov uas muab los ntawm pob zeb ntuj. Kev siv granite ua cov khoom siv tseem ceeb rau lub txaj granite thiab lwm yam khoom siv OEM granite tshwj xeeb yog qhov tseem ceeb hauv kev thawb cov ciam teb ntawm miniaturization. Rau cov chaw tsim khoom ntawm Wafer Processing Equipment, kev koom tes nrog tus kws tshaj lij hauv cov qauv granite siab yog thawj kauj ruam thiab tseem ceeb tshaj plaws rau kev ruaj ntseg kev sib tw hauv kev lag luam semiconductor thoob ntiaj teb.

Lub sijhawm tshaj tawm: Lub Kaum Ob Hlis-01-2025