Hauv kev tsim khoom siv semiconductor, qhov tseeb ntawm cov khoom siv tshuaj xyuas wafer ncaj qha txiav txim siab qhov zoo thiab cov txiaj ntsig ntawm cov chips. Raws li lub hauv paus txhawb nqa cov khoom tseem ceeb ntawm kev tshawb nrhiav, qhov ruaj khov ntawm cov khoom siv hauv paus ua lub luag haujlwm tseem ceeb hauv kev ua haujlwm ntev ntawm cov khoom siv. Granite thiab cam khwb cia hlau yog ob qho khoom siv hauv paus siv rau cov khoom siv tshuaj xyuas wafer. Kev tshawb fawb sib piv 10-xyoo tau qhia txog qhov sib txawv tseem ceeb ntawm lawv hauv cov nqe lus ntawm kev ruaj khov ntawm qhov ntev, muab cov ntaub ntawv tseem ceeb rau kev xaiv cov khoom siv.

Keeb Kwm thiab Kev Tsim Qauv ntawm Kev Sim

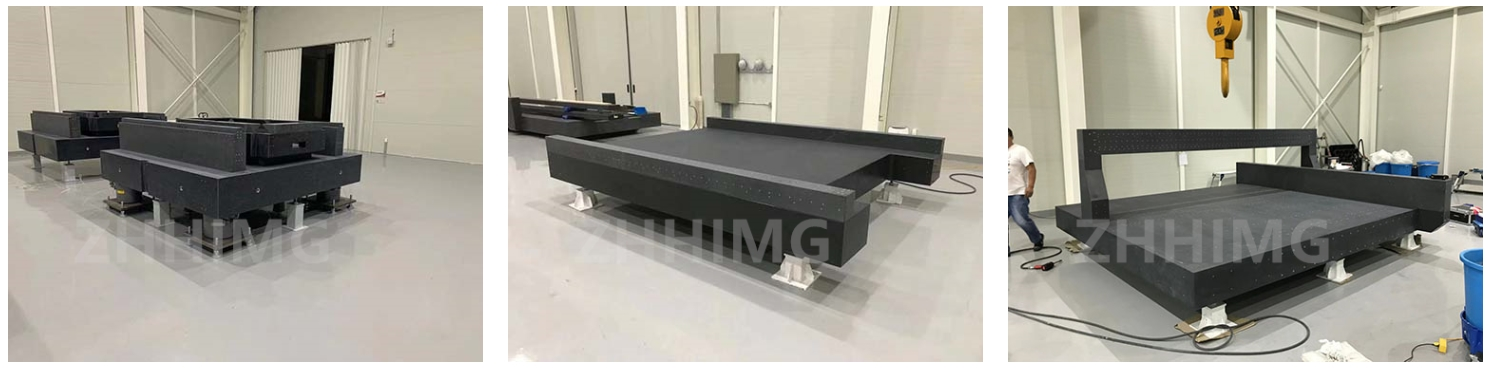

Cov txheej txheem tsim cov semiconductor wafers muaj cov kev cai siab heev rau kev kuaj pom qhov tseeb. Txawm tias qhov sib txawv ntawm micrometer-level tuaj yeem ua rau kev ua haujlwm ntawm cov chip poob qis lossis txawm tias scrapping. Txhawm rau tshawb nrhiav qhov ruaj khov ntawm cov granite thiab cam khwb cia hlau thaum siv ntev, pab pawg tshawb fawb tau tsim cov kev sim uas ua piv txwv rau cov chaw ua haujlwm tiag tiag. Cov qauv granite thiab cam khwb cia hlau ntawm tib qho kev qhia tau raug xaiv thiab muab tso rau hauv chav ib puag ncig uas qhov kub hloov pauv ntawm 15 ℃ txog 35 ℃ thiab cov av noo hloov pauv ntawm 30% txog 70% RH. Kev co tshuab thaum lub sijhawm ua haujlwm ntawm cov khoom siv tau ua piv txwv los ntawm lub rooj co. Cov qhov loj me tseem ceeb ntawm cov qauv tau ntsuas txhua peb lub hlis twg siv lub tshuab laser interferometer siab, thiab cov ntaub ntawv tau raug kaw tas li rau 10 xyoo.

Cov txiaj ntsig sim: Qhov zoo tshaj plaws ntawm granite

Kaum xyoo ntawm cov ntaub ntawv sim qhia tau hais tias lub granite substrate muaj kev ruaj khov zoo kawg nkaus. Nws cov coefficient ntawm thermal expansion yog qis heev, nruab nrab tsuas yog 4.6 × 10⁻⁶ / ℃. Nyob rau hauv kev hloov pauv kub hnyav, qhov sib txawv ntawm qhov ntev yeej ib txwm tswj tau hauv ± 0.001 hli. Thaum ntsib kev hloov pauv ntawm cov av noo, cov qauv ntom ntawm granite ua rau nws yuav luag tsis cuam tshuam, thiab tsis muaj kev hloov pauv ntawm qhov ntev uas ntsuas tau tshwm sim. Hauv qhov chaw ib puag ncig kev co tshuab, cov yam ntxwv zoo heev ntawm damping ntawm granite zoo nqus tau lub zog co, thiab qhov kev hloov pauv ntawm qhov ntev yog me me heev.

Qhov sib piv, rau cov hlau cam khwb cia substrate, nws qhov nruab nrab coefficient ntawm thermal expansion ncav cuag 11 × 10⁻⁶ / ℃ - 13 × 10⁻⁶ / ℃, thiab qhov siab tshaj plaws ntawm qhov ntev uas tshwm sim los ntawm kev hloov pauv kub hauv 10 xyoo yog ± 0.05 hli. Hauv qhov chaw noo noo, hlau cam khwb cia yog qhov yooj yim xeb thiab xeb. Qee cov qauv qhia txog kev hloov pauv hauv zos, thiab qhov sib txawv ntawm qhov ntev ntxiv nce ntxiv. Nyob rau hauv qhov kev ua ntawm kev co tshuab, hlau cam khwb cia muaj kev ua haujlwm tsis zoo ntawm kev co thiab nws qhov loj me hloov pauv ntau zaus, ua rau nws nyuaj rau ua kom tau raws li qhov xav tau ntawm kev tshuaj xyuas wafer.

Qhov laj thawj tseem ceeb rau qhov sib txawv ntawm kev ruaj khov

Granite tau tsim los ntawm ntau pua lab xyoo los ntawm cov txheej txheem geological. Nws cov qauv sab hauv yog ntom thiab sib xws, thiab cov pob zeb siv lead ua tau ruaj khov, tshem tawm kev ntxhov siab sab hauv los ntawm xwm. Qhov no ua rau nws tsis tshua muaj kev cuam tshuam rau kev hloov pauv ntawm cov yam ntxwv sab nraud xws li kub, av noo thiab kev co. Hlau cam khwb cia yog ua los ntawm cov txheej txheem casting thiab muaj cov qhov me me xws li qhov hws thiab cov xuab zeb hauv. Lub caij no, qhov kev ntxhov siab seem tsim thaum lub sijhawm casting yog qhov ua rau muaj kev hloov pauv ntawm qhov ntev raws li kev txhawb nqa ntawm ib puag ncig sab nraud. Cov khoom siv hlau ntawm cov hlau cam khwb cia ua rau nws yooj yim xeb vim av noo, ua kom cov qauv puas tsuaj sai dua thiab txo qhov ntev.

Qhov cuam tshuam rau cov khoom siv tshuaj xyuas wafer

Cov khoom siv tshuaj xyuas wafer raws li granite substrate, nrog nws cov kev ua haujlwm ruaj khov, tuaj yeem ua kom lub kaw lus tshuaj xyuas tswj tau qhov tseeb siab rau lub sijhawm ntev, txo qhov kev txiav txim siab tsis raug thiab kev tshawb pom tsis raug los ntawm cov khoom siv qhov tseeb drift, thiab txhim kho cov khoom tsim tau zoo heev. Lub caij no, qhov yuav tsum tau saib xyuas tsawg txo cov nqi tag nrho ntawm lub neej ntawm cov khoom siv. Cov khoom siv siv cov hlau cam khwb cia substrates, vim tsis ruaj khov qhov ntev, yuav tsum tau calibration thiab saib xyuas ntau zaus. Qhov no tsis yog tsuas yog ua rau cov nqi khiav lag luam nce ntxiv xwb tab sis kuj tseem yuav cuam tshuam rau qhov zoo ntawm kev tsim khoom semiconductor vim tsis txaus precision, ua rau muaj kev poob nyiaj txiag.

Nyob rau hauv qhov sib txawv ntawm kev lag luam semiconductor nrhiav kev ua kom raug dua thiab zoo dua, kev xaiv granite ua cov khoom siv tseem ceeb rau cov khoom siv tshuaj xyuas wafer yog qhov tsis ntseeg qhov kev txav mus los kom ntseeg tau tias cov khoom siv ua haujlwm tau zoo thiab txhim kho kev sib tw ntawm cov tuam txhab.

Lub sijhawm tshaj tawm: Tsib Hlis-14-2025