Hauv kev tsim khoom raug, kev nkag siab yuam kev feem ntau yog tias "qhov ceev dua = qhov muaj zog dua = qhov raug dua". Lub hauv paus granite, nrog qhov ceev ntawm 2.6-2.8g / cm³ (7.86g / cm³ rau cov hlau cam khwb cia), tau ua tiav qhov tseeb tshaj qhov ntawm micrometers lossis txawm tias nanometers. Tom qab qhov "counter-intuitive" no yog qhov sib koom ua ke ntawm mineralogy, mechanics thiab cov txheej txheem ua. Cov hauv qab no tshuaj xyuas nws cov ntsiab cai tshawb fawb los ntawm plaub qhov loj me.

1. Qhov Ceev ≠ Rigidity: Lub luag haujlwm txiav txim siab ntawm cov qauv khoom siv

Cov qauv siv lead ua "natural honeycomb" ntawm granite

Granite yog tsim los ntawm cov pob zeb siv lead ua xws li quartz (SiO₂) thiab feldspar (KAlSi₃O₈), uas tau sib txuas zoo los ntawm ionic / covalent bonds, tsim cov qauv zoo li honeycomb. Cov qauv no muab nws nrog cov yam ntxwv tshwj xeeb:

Lub zog compressive zoo ib yam li cov hlau cam khwb cia: ncav cuag 100-200 mpa (100-250 mpa rau grey cast iron), tab sis cov elastic modulus qis dua (70-100 gpa vs 160-200 gpa rau cam khwb cia), uas txhais tau tias nws tsis tshua muaj peev xwm hloov pauv yas hauv qab lub zog.

Kev tso tawm ntawm kev ntxhov siab sab hauv ntuj: Granite tau dhau los ua kev laus dhau ntau pua lab xyoo ntawm cov txheej txheem geological, thiab kev ntxhov siab sab hauv seem ze li xoom. Thaum cov hlau cam khwb cia txias (nrog rau qhov txias txias> 50 ℃ / s), kev ntxhov siab sab hauv siab txog li 50-100 mpa raug tsim, uas yuav tsum tau tshem tawm los ntawm kev ua kom sov. Yog tias kev kho mob tsis ua tiav, nws yuav ua rau deformation thaum siv ntev.

2. Cov qauv hlau "ntau qhov tsis zoo" ntawm cov hlau cam khwb cia

Hlau cam khwb cia yog hlau-carbon alloy, thiab nws muaj qhov tsis zoo xws li flake graphite, pores thiab shrinkage porosity sab hauv.

Graphite fragmentation matrix: Flake graphite yog sib npaug rau sab hauv "microcracks", ua rau 30% -50% txo qis hauv thaj chaw thauj khoom tiag tiag ntawm cov hlau cam khwb cia. Txawm hais tias lub zog compressive siab, lub zog flexural qis (tsuas yog 1/5-1/10 ntawm lub zog compressive), thiab nws yooj yim tawg vim muaj kev ntxhov siab hauv zos.

Kev faib tawm ntawm cov khoom loj tab sis tsis sib npaug: Cov hlau cam khwb cia muaj 2% txog 4% carbon. Thaum lub sijhawm casting, kev sib cais ntawm cov khoom carbon tuaj yeem ua rau muaj kev hloov pauv ntawm qhov ceev ntawm ± 3%, thaum granite muaj kev faib tawm ntawm cov khoom siv minerals ntau dua 95%, ua kom muaj kev ruaj khov ntawm cov qauv.

Qhov thib ob, qhov zoo ntawm qhov ceev tsawg: kev tswj ob zaug ntawm cua sov thiab kev co

Qhov "zoo dua qub" ntawm kev tswj hwm kev hloov pauv thermal

Tus coefficient ntawm thermal expansion sib txawv heev: granite yog 0.6-5 × 10⁻⁶ / ℃, thaum cam khwb cia hlau yog 10-12 × 10⁻⁶ / ℃. Siv lub hauv paus 10-meter ua piv txwv. Thaum qhov kub hloov pauv los ntawm 10 ℃:

Granite nthuav dav thiab cog lus: 0.06-0.5 hli

Kev nthuav dav thiab kev cog lus ntawm cov hlau cam khwb cia: 1-1.2 hli

Qhov sib txawv no ua rau granite yuav luag "xoom deformation" nyob rau hauv ib puag ncig tswj qhov kub thiab txias (xws li ± 0.5 ℃ hauv lub chaw ua haujlwm semiconductor), thaum cov hlau cam khwb cia xav tau lub kaw lus them nyiaj thermal ntxiv.

Qhov sib txawv ntawm kev ua kom sov: Lub thermal conductivity ntawm granite yog 2-3W / (m · K), uas tsuas yog 1 / 20-1 / 30 ntawm cov hlau cam khwb cia (50-80W / (m · K)). Hauv cov xwm txheej cua sov ntawm cov khoom siv (xws li thaum lub cev muaj zog kub txog 60 ℃), qhov kub ntawm qhov chaw ntawm granite tsawg dua 0.5 ℃ / m, thaum cov hlau cam khwb cia tuaj yeem ncav cuag 5-8 ℃ / m, ua rau muaj kev nthuav dav hauv zos tsis sib xws thiab cuam tshuam rau qhov ncaj ntawm txoj kev qhia.

2. Qhov "natural damping" effect ntawm kev tswj kev co

Lub tshuab ua kom lub zog ntawm cov ciam teb sab hauv ploj mus: Cov pob zeb me me tawg thiab cov ciam teb ntawm cov pob zeb granite tuaj yeem ua rau lub zog co sai sai ploj mus, nrog rau qhov piv ntawm damping ntawm 0.3-0.5 (thaum rau cov hlau cam khwb nws tsuas yog 0.05-0.1). Qhov kev sim qhia tau tias ntawm kev co ntawm 100Hz:

Nws siv sijhawm 0.1 vib nas this rau qhov loj ntawm granite kom lwj mus rau 10%

Cov hlau cam khwb cia siv sijhawm 0.8 vib nas this

Qhov sib txawv no ua rau granite ruaj khov tam sim ntawd hauv cov khoom siv txav mus los ceev (xws li 2m / s scanning ntawm lub taub hau txheej), zam qhov tsis zoo ntawm "cov cim kev co".

Qhov cuam tshuam rov qab ntawm qhov hnyav inertial: Qhov ceev qis txhais tau tias qhov hnyav me dua hauv tib lub ntim, thiab lub zog inertial (F = ma) thiab momentum (p = mv) ntawm qhov txav mus los qis dua. Piv txwv li, thaum lub thav duab granite gantry 10-meter (hnyav 12 tons) raug nrawm mus rau 1.5G piv rau lub thav duab hlau cam khwb cia (20 tons), qhov xav tau lub zog tsav tsheb raug txo los ntawm 40%, qhov cuam tshuam pib-nres raug txo qis, thiab qhov tseeb ntawm qhov chaw tau txhim kho ntxiv.

Iii. Kev tawg ua qhov tshiab hauv kev ua cov txheej txheem ua tiav uas "tsis muaj kev cuam tshuam rau qhov ceev"

1. Kev hloov kho kom haum rau kev ua tiav ultra-precision

Kev tswj hwm "Crystal-level" ntawm kev sib tsoo thiab polishing: Txawm hais tias qhov nyuaj ntawm granite (6-7 ntawm Mohs scale) siab dua li ntawm cov hlau cam khwb cia (4-5 ntawm Mohs scale), nws cov qauv minerals yog sib xws thiab tuaj yeem tshem tawm atomically los ntawm pob zeb diamond abrasive + magnetorheological polishing (ib qho polishing thickness < 10nm), thiab qhov roughness ntawm qhov chaw Ra tuaj yeem ncav cuag 0.02μm (qib iav). Txawm li cas los xij, vim muaj cov khoom graphite mos hauv cov hlau cam khwb cia, "furplough effect" feem ntau tshwm sim thaum sib tsoo, thiab qhov roughness ntawm qhov chaw nyuaj rau qis dua Ra 0.8μm.

Qhov zoo ntawm "kev ntxhov siab tsawg" ntawm CNC machining: Thaum ua granite, lub zog txiav tsuas yog 1/3 ntawm cov hlau cam khwb cia (vim nws qhov ceev tsawg thiab cov qauv elastic me me), uas ua rau muaj kev sib hloov ceev dua (100,000 revolutions ib feeb) thiab cov nqi pub (5000mm / feeb), txo cov cuab yeej hnav thiab txhim kho kev ua haujlwm zoo. Ib qho kev ua haujlwm tsib-axis qhia tau hais tias lub sijhawm ua tiav ntawm granite guide rail grooves yog 25% luv dua li cov hlau cam khwb cia, thaum qhov tseeb tau txhim kho mus rau ± 2μm.

2. Qhov sib txawv ntawm "cov nyhuv sib sau ua ke" ntawm cov yuam kev sib dhos

Qhov kev sib xyaw ua ke ntawm qhov hnyav ntawm cov khoom siv txo qis: Cov khoom siv xws li lub cev muaj zog thiab cov hlau qhia kev sib txuas nrog cov hauv paus qis qis tuaj yeem ua kom sib dua tib lub sijhawm. Piv txwv li, thaum lub zog ntawm lub cev muaj zog linear raug txo los ntawm 30%, nws cov cua sov tsim thiab kev co kuj txo qis raws li, tsim ib lub voj voog zoo ntawm "kev txhim kho qhov tseeb - txo qis kev siv hluav taws xob".

Kev khaws cia kom raug mus sij hawm ntev: Qhov kev tiv thaiv corrosion ntawm granite yog 15 npaug ntawm cov hlau cam khwb cia (quartz tiv taus acid thiab alkali erosion). Hauv ib puag ncig semiconductor acid mist, qhov kev hloov pauv ntawm qhov chaw tom qab 10 xyoo ntawm kev siv yog tsawg dua 0.02μm, thaum cov hlau cam khwb cia yuav tsum tau sib tsoo thiab kho txhua xyoo, nrog rau qhov yuam kev ntawm ± 20μm.

Iv. Cov Pov Thawj Kev Lag Luam: Piv txwv zoo tshaj plaws ntawm Qhov Ceev Tsawg ≠ Kev Ua Haujlwm Tsawg

Cov khoom siv kuaj semiconductor

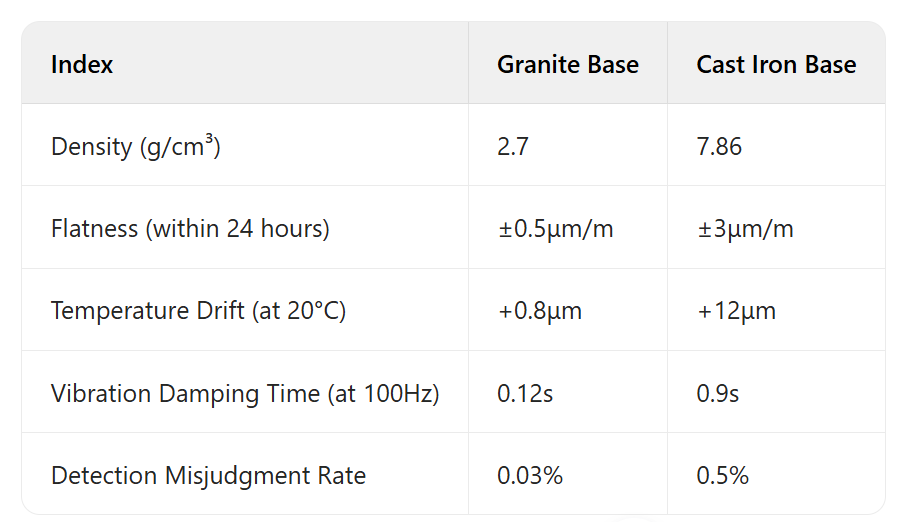

Cov ntaub ntawv sib piv ntawm ib qho wafer tshuaj xyuas platform:

2. Cov cuab yeej siv kho qhov muag uas meej

Lub cuab yeej ntes infrared ntawm NASA lub James Webb Telescope yog ua los ntawm granite. Nws yog los ntawm kev siv nws qhov ceev tsawg (txo cov khoom thauj ntawm lub satellite) thiab qhov nthuav dav thermal qis (ruaj khov ntawm qhov kub qis heev ntawm -270 ℃) uas ua kom muaj qhov tseeb ntawm nano-level optical alignment, thaum qhov kev pheej hmoo ntawm cov hlau cam khwb cia yuav tawg ntawm qhov kub qis raug tshem tawm.

Xaus lus: "Kev tawm tsam kev nkag siab zoo" kev tsim kho tshiab hauv kev tshawb fawb txog cov ntaub ntawv

Qhov zoo ntawm qhov tseeb ntawm cov granite bases yeej yog nyob rau hauv cov khoom siv logic yeej ntawm "structural uniformity> density, thermal shock stability> simple rigidity". Tsis yog nws qhov tsawg density tsis yog qhov tsis muaj zog xwb, tab sis nws kuj tau ua tiav qhov kev dhia hauv qhov tseeb los ntawm kev ntsuas xws li txo inertia, optimizing thermal control, thiab adapting rau ultra-precision processing. Qhov xwm txheej no qhia txog txoj cai tseem ceeb ntawm kev tsim khoom precision: cov khoom siv yog qhov sib npaug ntawm ntau qhov ntau thiab tsawg es tsis yog kev sib sau ua ke ntawm ib qho cim qhia. Nrog rau kev txhim kho ntawm nanotechnology thiab kev tsim khoom ntsuab, cov khoom siv granite qis-density thiab kev ua tau zoo siab tau rov txhais dua qhov kev xav ntawm kev lag luam ntawm "hnyav" thiab "lub teeb", "rigid" thiab "yoog tau", qhib txoj hauv kev tshiab rau kev tsim khoom siab.

Lub sijhawm tshaj tawm: Tsib Hlis-19-2025