cov

Hauv kev lag luam CNC lej tswj cov cuab yeej, precision, stability thiab durability yog cov cim tseem ceeb rau kev ntsuas kev ua tau zoo ntawm cov cuab yeej. Granite, nrog nws cov khoom zoo ntawm lub cev thiab tshuaj lom neeg, tau maj mam dhau los ua cov khoom tseem ceeb hauv kev tsim cov cuab yeej CNC thiab tau siv dav hauv ntau yam khoom siv tseem ceeb, txhaj tshuaj tshiab rau hauv kev tsim kho kev lag luam. cov

I. Daim Ntawv Thov Scenario ntawm Granite hauv CNC Numerical Control Equipment

High-precision machining center puag

Hauv cov teb xws li precision pwm ua thiab aviation qhov chaw tsim khoom, cov kev xav tau siab heev tau muab tso rau ntawm qhov chaw raug thiab rov ua qhov tseeb ntawm cov chaw machining. Granite, nrog nws cov kev ruaj ntseg zoo, feem ntau yog siv los ua cov khoom siv rau high-end machining chaw. Nws cov qauv tuab thiab siab rigidity tuaj yeem txhawb nqa cov txheej txheem tseem ceeb ntawm lub tshuab ntxaiv thiab qhia kev sib tw, txo cov kev ua yuam kev los ntawm kev ua kom muaj zog. Piv txwv li, thaum ua cov pwm ntawm aero engine blades nrog complex curved nto, lub machining chaw siv lub hauv paus granite tuaj yeem ua kom tiav qhov kev ua tiav ntawm cov cuab yeej txoj kev thiab txhim kho qhov tseeb ntawm cov pwm. cov

2. Peb-coordinate ntsuas tshuab platform

Lub tshuab ntsuas peb-coordinate yog cov cuab yeej tseem ceeb rau kev tshuaj xyuas zoo hauv CNC machining, thiab nws qhov ntsuas qhov tseeb cuam tshuam ncaj qha rau cov khoom zoo. Granite platforms, nrog rau lawv cov flatness tsis tshua muaj siab (txog ± 0.1μm / m) thiab tsawg heev deg roughness (Ra≤0.02μm), muab ib tug ruaj khov siv nto rau ntsuas probes. Thaum kuaj xyuas qhov ntev, cov duab thiab qhov chaw kam rau siab ntawm qhov precision, granite platforms tuaj yeem zam kev ntsuas qhov yuam kev los ntawm lawv tus kheej deformation lossis qhov tsis sib xws, kom ntseeg tau qhov tseeb thiab kev ntseeg siab ntawm cov ntaub ntawv tshuaj xyuas. cov

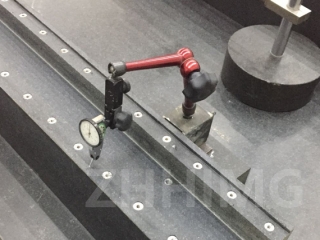

3. Qhia cov ntsia hlau rau CNC tshuab cuab yeej

Qhov kev ua tau zoo ntawm cov lus qhia kev tsheb ciav hlau txiav txim siab qhov smoothness thiab raug ntawm lub tshuab cuab yeej txav. Granite qhia rails muaj cov coefficient tsawg ntawm kev sib txhuam thiab muaj zog hnav tsis kam. Piv nrog rau cov ntawv qhia hlau, lawv tuaj yeem txo qhov hnav ntawm qhov txav thiab txo qhov zaus ntawm kev saib xyuas. Meanwhile, nws zoo heev damping kev ua tau zoo nqus tau cov kev co thaum lub sij hawm lub lag luam ntawm lub tshuab cuab tam thiab txhim kho qhov zoo ntawm machined nto. Nyob rau hauv kev kub ceev txiav cov txheej txheem, granite qhia rails tuaj yeem khaws cov cuab yeej txiav hauv lub xeev ruaj khov, txo qhov roughness ntawm lub workpiece, thiab txhim kho kev ua haujlwm thiab cov khoom zoo. cov

4. Hluav taws xob tawm machining tshuab cuab yeej worktable

Thaum lub sij hawm hluav taws xob tawm machining txheej txheem, kub siab thiab electromagnetic cuam tshuam yog generated, uas tso siab xav tau kev ruaj ntseg thiab rwb thaiv tsev ntawm worktable. Granite tsis tsuas yog muaj kev ruaj ntseg zoo heev, muaj peev xwm tiv taus qhov kub thiab txias thaum lub sijhawm ua haujlwm, tab sis kuj muaj cov khoom siv hluav taws xob zoo thiab tsis cuam tshuam los ntawm electromagnetic cuam tshuam. Yog li ntawd, granite workbenches tuaj yeem muab qhov chaw ua haujlwm ruaj khov rau kev siv hluav taws xob tawm hluav taws xob, ua kom cov khoom raug thiab qhov zoo. cov

Ii. Core Advantages ntawm Granite hauv CNC Numerical Control Equipment

Zoo thermal stability

Thaum lub sijhawm ua haujlwm tas mus li ntawm CNC cov cuab yeej, cov cua kub ntau yog tsim, ua rau lub thermal expansion thiab contraction ntawm cov khoom siv. Cov coefficient ntawm thermal expansion ntawm granite yog tsawg heev (tsuas yog 4-8 × 10⁻⁶ / ℃), thiab nws qhov loj me tseem yuav luag tsis hloov thaum qhov kub thiab txias hloov, uas tuaj yeem zam kev ua yuam kev thiab ntsuas qhov sib txawv los ntawm thermal deformation. Piv txwv li, nyob rau hauv high-temperature ib puag ncig, CNC cov cuab yeej nrog granite hauv paus tseem tuaj yeem tswj xyuas qhov kev ua haujlwm ruaj khov, kom ntseeg tau tias cov khoom zoo tsis cuam tshuam los ntawm qhov kub thiab txias. cov

2. Kev ua haujlwm zoo tiv thaiv kev vibration

Thaum lub sijhawm CNC machining txheej txheem, kev ua haujlwm siab ceev ntawm lub tshuab cuab yeej thiab lub zog txiav yuav ua rau muaj kev vibration, cuam tshuam rau kev ua haujlwm raug thiab qhov zoo. Cov qauv siv lead ua tshwj xeeb hauv granite endows nws nrog kev ua haujlwm zoo damping, ua rau nws ua kom nrawm nrawm rau sab nraud vibration zog thiab txo qis kev cuam tshuam. Kev sim cov ntaub ntawv qhia tau hais tias damping piv ntawm granite tuaj yeem ncav cuag 0.05-0.1, uas yog 5-10 npaug ntawm cov ntaub ntawv hlau. Nws tuaj yeem txo cov cuab yeej kev co thiab qhov waviness ntawm lub workpiece nto, thiab txhim kho kev ua haujlwm raug thiab nto tiav. cov

3. High rigidity thiab hnav tsis kam

Granite muaj qhov ntom ntom (txog 2.6-3.0g / cm³) thiab hardness zoo (nrog Mohs hardness ntawm 6-7), thiab nws nta zoo heev rigidity thiab hnav tsis kam. Thaum raug rau cov khoom hnyav thiab nquag txav ntawm cov khoom siv CNC, cov khoom siv granite tsis tuaj yeem ua rau deformation lossis hnav thiab tuaj yeem tswj tau lub xeev siab rau lub sijhawm ntev. Raws li kev txheeb cais, lub sijhawm ceev ceev ntawm CNC cov cuab yeej siv cov khoom siv granite tuaj yeem yog 3 mus rau 5 zaug ntev dua li cov khoom siv hlau tsoos, txo cov khoom siv tu cov nqi thiab sijhawm poob. cov

4. Muaj zog chemical stability

Nyob rau hauv cov txheej txheem CNC machining, tshuaj reagents xws li txiav cov kua thiab lubricants feem ntau yog siv, thiab cov tshuaj no yuav ua rau corrosion rau cov khoom siv. Granite muaj cov khoom siv tshuaj ruaj khov, qhov dav pH kam rau ua ntau yam (1-14), tuaj yeem tiv thaiv kev yaig ntawm cov tshuaj lom neeg, thiab tsis muaj xeb lossis xeb. Cov yam ntxwv no tsis tsuas yog txuas ntxiv lub neej kev pab cuam ntawm cov khoom siv, tab sis kuj ua kom huv si ntawm qhov chaw ua haujlwm, tsis txhob cuam tshuam rau cov khoom zoo vim muaj tshuaj lom neeg. cov

Tawm tsam cov keeb kwm yav dhau ntawm CNC cov lej tswj cov cuab yeej kev lag luam kev lag luam txuas ntxiv ntawm kev ua haujlwm siab thiab kev ua haujlwm siab, granite, nrog nws qhov zoo xws li thermal stability, kev co kuj, siab rigidity thiab tshuaj stability, plays lub luag hauj lwm irreplaceable nyob rau hauv ntau yam khoom tseem ceeb. Nrog rau kev nce qib ntawm kev siv thev naus laus zis, cov ntaub ntawv granite yuav siv dav hauv CNC teb, txhawb kev lag luam los txhim kho kev ua tau zoo dua thiab zoo dua..

Post lub sij hawm: May-24-2025