Hauv kev hloov pauv sai ntawm kev tsim khoom siab heev, kev ua kom raug tseem yog qhov tseem ceeb tshaj plaws. Niaj hnub no, kev tsim kho tshiab tau teeb tsa los txhais cov qauv kev lag luam dua tshiab: Precision Marble Three-Axis Gantry Platform, ib qho txuj ci tseem ceeb ntawm kev tsim kho uas sib xyaw cov granite ntuj tsim kev ruaj khov nrog kev tsim kho tshuab tshiab kom ua tiav qhov tseeb micron-level uas yav dhau los xav tias tsis tuaj yeem ua tiav hauv kev siv hauv kev lag luam.

Kev Tshawb Fawb Tom Qab Kev Ruaj Ntseg

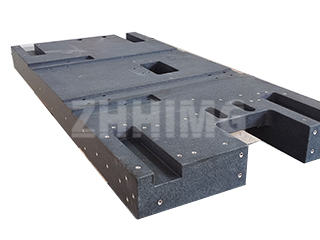

Hauv plawv ntawm qhov kev hloov pauv thev naus laus zis no yog kev xaiv cov khoom siv uas tsis tau xav txog: granite ntuj. Lub platform lub hauv paus marble 1565 x 1420 x 740 mm precision-machined tsis yog tsuas yog kev tsim qauv zoo nkauj xwb - nws yog kev daws teeb meem kev tshawb fawb rau qhov kev sib tw qub ntawm kev tswj hwm kev ruaj khov hauv cov kab ke siab. "Granite tus coefficient qis heev ntawm thermal expansion (2.5 x 10^-6 /°C) thiab cov yam ntxwv zoo heev damping muab lub hauv paus uas tiv taus qhov kub thiab txias ib puag ncig thiab kev co tshuab zoo dua li cov qauv hlau ib txwm muaj," piav qhia Dr. Emily Chen, tus thawj coj mechanical engineer ntawm Precision Engineering Research Institute.

Qhov txiaj ntsig ntuj tsim no txhais tau ncaj qha rau cov ntsuas kev ua tau zoo uas tig lub taub hau thoob plaws kev lag luam. Lub platform ua tiav ± 0.8 μm rov ua dua - txhais tau tias nws tuaj yeem rov qab mus rau txhua qhov chaw nrog qhov sib txawv me dua qhov ntev ntawm lub teeb pom kev zoo - thiab ± 1.2 μm qhov tseeb ntawm qhov chaw tom qab them nyiaj, teeb tsa tus qauv tshiab rau cov kab ke tswj kev txav mus los.

Kev Ua Zoo Tshaj Plaws hauv Kev Txav Mus Los

Ntxiv rau nws lub hauv paus ruaj khov, lub platform peb-axis gantry tsim muaj ntau yam kev tsim kho tshiab. Lub X-axis muaj lub kaw lus tsav ob chav uas tshem tawm qhov kev hloov pauv torsional thaum lub sijhawm txav mus los ceev ceev, thaum ob qho tib si X thiab Y axes xa 750 hli ntawm kev mus ncig zoo nrog ≤8 μm ncaj hauv ob qho tib si kab rov tav thiab ntsug. Qib ntawm qhov tseeb geometric no ua kom ntseeg tau tias txawm tias cov kab ke 3D nyuaj tseem tswj tau qhov tseeb sub-micron.

Lub peev xwm txav mus los ntawm lub kaw lus muaj qhov sib npaug zoo kawg nkaus ntawm kev ceev thiab kev raug. Txawm hais tias nws qhov ceev tshaj plaws ntawm 1 mm/s yuav zoo li tsis hnyav, nws tau tsim kho rau cov ntawv thov uas xav tau kev tswj hwm zoo thiab kev luam theej qeeb - qhov twg qhov tseeb tseem ceeb dua li kev txav mus los sai. Ntawm qhov tod tes, lub peev xwm ua kom nrawm 2 G ua kom muaj kev ua haujlwm pib-nres, tseem ceeb rau kev tswj hwm cov khoom siv hauv cov txheej txheem tshuaj xyuas qhov tseeb.

Nrog rau lub peev xwm thauj khoom 40 kg thiab qhov kev daws teeb meem 100 nm (0.0001 mm), lub platform txuas qhov sib txawv ntawm kev tswj hwm me me thiab kev ruaj khov hauv kev lag luam - qhov kev hloov pauv tau yooj yim uas ua rau muaj kev txaus siab thoob plaws hauv kev tsim khoom.

Kev Hloov Pauv Cov Lag Luam Tseem Ceeb

Cov txiaj ntsig ntawm qhov kev tshawb pom tseeb no nthuav dav mus rau ntau lub lag luam high-tech:

Hauv kev tsim khoom semiconductor, qhov twg txawm tias qhov tsis zoo ntawm nanometer-scale tuaj yeem ua rau cov chips tsis muaj txiaj ntsig, lub platform qhov kev ruaj khov yog qhov hloov pauv loj heev rau kev tshuaj xyuas wafer thiab cov txheej txheem sib dhos photolithography. "Peb pom cov nqi kuaj pom qhov tsis zoo nce ntxiv los ntawm 37% hauv kev sim thaum ntxov," Michael Torres, tus kws ua haujlwm laus ntawm lub tuam txhab tsim khoom siv semiconductor ua tus thawj coj qhia. "Lub hauv paus marble lub vibration damping tau tshem tawm qhov micro-wobble uas yav dhau los zais cov yam ntxwv sub-50 nm."

Kev tsim khoom siv kho qhov muag kom raug yog lwm qhov txiaj ntsig. Cov txheej txheem txhuam thiab sib dhos lub lens uas ib zaug xav tau ntau teev ntawm kev kho kom raug tes tam sim no tuaj yeem ua tau automation nrog lub platform qhov chaw sub-micron, txo cov sijhawm tsim khoom thaum txhim kho kev ua haujlwm kho qhov muag.

Hauv kev tshawb fawb txog kev kho mob, lub platform no ua rau muaj kev vam meej hauv kev tswj hwm ib lub cell thiab kev thaij duab microscopic siab. Dr. Sarah Johnson ntawm Stanford's Biomedical Engineering Department tau hais tias, "Qhov ruaj khov tso cai rau peb kom tsom mus rau cov qauv cell rau lub sijhawm ntev, ntes cov duab time-lapse uas qhia txog cov txheej txheem ntawm lub cev uas yav dhau los zais los ntawm cov khoom siv drift."

Lwm cov ntawv thov tseem ceeb suav nrog cov tshuab ntsuas kev sib koom ua ke siab (CMMs), cov khoom ntim khoom siv hluav taws xob me me, thiab cov cuab yeej tshawb fawb siab heev - txhua qhov chaw uas lub platform txoj kev sib xyaw ua ke ntawm kev ua kom raug, kev ruaj khov, thiab lub peev xwm thauj khoom daws tau cov kev txwv kev siv tshuab ntev.

Yav Tom Ntej ntawm Kev Tsim Khoom Siv Ultra-Precision

Thaum kev tsim khoom tseem niaj hnub thawb mus rau qhov me me thiab cov qauv kev ua tau zoo dua, qhov kev thov rau cov txheej txheem tso cai siab heev yuav tsuas yog nce ntxiv. Lub Precision Marble Three-Axis Gantry Platform tsis yog tsuas yog kev txhim kho me me xwb tab sis kuj yog kev hloov pauv tseem ceeb hauv kev ua tiav qhov tseeb - siv cov khoom siv ntuj tsim nrog rau kev tsim kho siab heev es tsis txhob cia siab rau cov txheej txheem them nyiaj nyuaj.

Rau cov chaw tsim khoom uas tab tom nrhiav kev cov nyom ntawm Kev Lag Luam 4.0, lub platform no muab kev pom rau yav tom ntej ntawm kev tsim khoom precision. Nws yog yav tom ntej uas txoj kab ntawm "kev ua haujlwm precision hauv chav kuaj" thiab "kev tsim khoom lag luam" txuas ntxiv mus tsis meej, ua rau muaj kev tsim kho tshiab uas yuav hloov txhua yam los ntawm cov khoom siv hluav taws xob tiam tom ntej mus rau cov khoom siv kho mob cawm siav.

Raws li ib tug kws tshuaj ntsuam xyuas kev lag luam tau hais tias: "Hauv lub ntiaj teb ntawm kev tsim khoom raug, kev ruaj khov tsis yog ib qho tshwj xeeb xwb - nws yog lub hauv paus uas txhua qhov kev nce qib lwm yam tau tsim los. Lub platform no tsis yog tsuas yog tsa tus qauv xwb; nws rov tsim dua tag nrho."

Lub sijhawm tshaj tawm: Lub Kaum Hli-31-2025