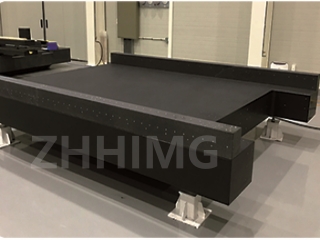

Hauv cov xwm txheej ua tiav siab ntawm cov tshuab cim picosecond-level laser, lub hauv paus, ua lub hauv paus tseem ceeb ntawm cov khoom siv, nws cov khoom siv xaiv ncaj qha txiav txim siab qhov ruaj khov ntawm qhov ua tiav. Granite thiab cam khwb cia hlau yog ob yam khoom siv rau kev tsim khoom hauv paus. Tsab xov xwm no yuav ua qhov kev sib piv los ntawm cov yam ntxwv xws li cov khoom siv lub cev, lub hauv paus ntsiab lus ntawm kev txo qhov tseeb, thiab cov ntaub ntawv siv tau, muab lub hauv paus kev tshawb fawb rau kev txhim kho cov khoom siv.

I. Qhov Sib Txawv ntawm Cov Khoom Siv: Lub Hauv Paus ntawm Kev Ua Haujlwm Tseeb

Granite yog pob zeb igneous ntuj, tsim los ntawm kev sib xyaw ua ke ntawm cov zaub mov xws li quartz thiab feldspar sab hauv. Nws yog tus cwj pwm los ntawm cov qauv ntom thiab siab hardness. Nws qhov ceev feem ntau yog ntawm 2.7 thiab 3.1g / cm³, thiab nws cov coefficient ntawm thermal expansion yog qis heev, kwv yees li (4-8) × 10⁻⁶ / ℃, uas tuaj yeem tiv taus qhov cuam tshuam ntawm kev hloov pauv kub rau qhov tseeb ntawm cov khoom siv. Tsis tas li ntawd, qhov tshwj xeeb microstructure ntawm granite muab nws nrog kev ua tau zoo heev damping, ua rau nws sai sai nqus tau lub zog sab nraud vibration thiab txo qhov cuam tshuam ntawm kev co ntawm kev ua tiav qhov tseeb.

Hlau cam khwb cia, ua cov khoom siv kev lag luam ib txwm muaj, muaj qhov ceev ntawm kwv yees li 7.86g / cm³, lub zog compressive siab, tab sis kub

Tus lej nthuav dav (kwv yees li 12 × 10⁻⁶ / ℃) yog 1.5-3 npaug ntawm granite. Ntxiv mus, muaj cov qauv graphite flake hauv cov hlau cam khwb cia. Thaum siv ntev, cov qauv no yuav ua rau muaj kev ntxhov siab, cuam tshuam rau kev ruaj khov ntawm cov khoom siv thiab tom qab ntawd ua rau qhov kev ua haujlwm raug txo qis.

II. Kev Ua Kom Me Nyuam Ua Kom Zoo Hauv Kev Siv Tshuab Picosecond

Kev ua laser theem Picosecond muaj qhov yuav tsum tau ua kom ruaj khov rau ib puag ncig. Txhua qhov kev hloov pauv me me ntawm cov khoom siv hauv paus yuav raug nthuav dav rau hauv cov txiaj ntsig ua tiav. Kev hloov pauv kub, kev co los ntawm kev ua haujlwm ntawm cov khoom siv, kev qaug zog thaum lub sijhawm ntev, thiab lwm yam, yog cov yam tseem ceeb uas ua rau qhov tseeb tsis zoo.

Thaum qhov kub hloov pauv, qhov loj ntawm granite hloov me ntsis vim nws cov coefficient qis ntawm thermal expansion. Cov coefficient thermal expansion loj ntawm cov hlau cam khwb cia yuav ua rau lub hauv paus raug deformation uas nyuaj rau pom nrog lub qhov muag liab qab. Qhov deformation no yuav cuam tshuam ncaj qha rau kev ruaj khov ntawm txoj kev laser optical thiab ua rau qhov chaw cim hloov pauv. Hais txog kev co, qhov siab damping ntawm granite tuaj yeem txo 100Hz kev co hauv 0.12 vib nas this, thaum hlau cam khwb cia xav tau 0.9 vib nas this. Nyob rau hauv cov xwm txheej kev co siab, qhov tseeb ntawm cov khoom siv nrog cov hlau cam khwb cia muaj feem cuam tshuam ntau dua.

III. Kev Sib Piv ntawm Cov Ntaub Ntawv Precision Attenuation

Raws li kev sim ntawm cov tsev kawm ntawv tshaj lij, thaum lub sijhawm ua haujlwm picosecond laser cim tas mus li 8-teev, qhov kev txo qis ntawm XY-axis qhov tseeb ntawm cov khoom siv nrog lub hauv paus granite yog nyob rau hauv ± 0.5μm. Qhov kev txo qis ntawm cov khoom siv hlau cam khwb cia ncav cuag ± 3μm, nrog qhov sib txawv tseem ceeb. Hauv ib puag ncig simulated nrog qhov kub hloov pauv ntawm 5 ℃, qhov yuam kev thermal deformation ntawm cov khoom siv granite tsuas yog + 0.8μm, thaum cov khoom siv hlau cam khwb cia siab txog + 12μm.

Tsis tas li ntawd xwb, los ntawm qhov kev siv mus sij hawm ntev, qhov kev txiav txim tsis raug ntawm cov hauv paus granite tsuas yog 0.03% xwb, thaum qhov kev txiav txim tsis raug ntawm cov hauv paus hlau cam khwb cia yog siab txog 0.5% vim muaj teeb meem kev ruaj khov ntawm cov qauv. Cov ntaub ntawv no qhia tau tias nyob rau hauv qhov yuav tsum tau ua kom raug ntawm picosecond-level processing, qhov zoo ntawm kev ruaj khov ntawm cov hauv paus granite yog qhov tseem ceeb.

Iv. Cov Lus Qhia Txog Kev Txhim Kho Dua Tshiab thiab Cov Kev Siv Tau Zoo

Rau cov lag luam uas nrhiav kev ua tiav qhov tseeb tshaj plaws, kev hloov kho lub hauv paus hlau cam khwb cia mus rau lub hauv paus granite yog ib txoj hauv kev zoo los txhim kho kev ua haujlwm ntawm cov khoom siv. Thaum lub sijhawm hloov kho, yuav tsum tau them sai sai rau qhov tseeb ntawm kev ua tiav ntawm lub hauv paus granite kom ntseeg tau tias qhov chaw tiaj tus ua tau raws li qhov yuav tsum tau tsim. Tib lub sijhawm, ua ke nrog cov khoom siv pabcuam xws li lub kaw lus cais kev co ntawm huab cua, kev ua haujlwm tiv thaiv kev co ntawm cov khoom siv tuaj yeem ua kom zoo dua.

Tam sim no, hauv kev lag luam xws li kev tsim cov khoom siv semiconductor thiab kev ua cov khoom siv optical component, cov tshuab laser marking nrog cov hauv paus granite tau siv dav, ua rau cov khoom tsim tau zoo dua thiab ua haujlwm tau zoo dua. Piv txwv li, tom qab ib lub tuam txhab tsim cov khoom siv optical component tau hloov kho cov khoom siv hlau cam khwb cia, qhov kev tsim nyog ntawm cov khoom tau nce ntxiv los ntawm 82% mus rau 97%, thiab kev ua haujlwm tau zoo dua.

Xaus lus, hauv kev txhim kho lub hauv paus ntawm picosecond-level laser marking tshuab, granite, nrog nws qhov kev ruaj khov thermal zoo heev, kev ua haujlwm siab damping thiab lub peev xwm khaws cia ntev, tau dhau los ua qhov kev xaiv zoo tshaj plaws zoo dua li cov hlau cam khwb cia. Cov lag luam tuaj yeem xaiv cov ntaub ntawv tseem ceeb raws li lawv tus kheej cov kev xav tau ua thiab cov peev nyiaj kom ua tiav kev txhim kho tag nrho ntawm kev ua haujlwm ntawm cov khoom siv.

Lub sijhawm tshaj tawm: Tsib Hlis-19-2025