Hauv cov chaw ua haujlwm nruj heev ntawm kev tsim khoom siab-txij li tsheb thiab aerospace mus rau cov khoom siv hluav taws xob siab heev-qhov sib txawv rau qhov yuam kev tsis muaj. Thaum Granite Surface Plates ua haujlwm ua lub hauv paus rau kev ntsuas dav dav, Granite Inspection Plate yog qhov tshwj xeeb, ruaj khov benchmark mob siab rau kev txheeb xyuas cov khoom thiab kev pab sib dhos. Nws yog lub cuab yeej tseem ceeb siv los txheeb xyuas cov geometry sab nraud, qhov sib txawv ntawm qhov ntev, thiab qhov tiaj tus ntawm cov khoom muaj nqis siab, kom ntseeg tau tias lawv ua tau raws li cov kev cai nruj ntawm kev tsim kho niaj hnub.

Lub Ntsiab Cai ntawm Ultra-Stable Datum

Lub luag haujlwm tseem ceeb ntawm Granite Inspection Plate yog nyob ntawm nws qhov kev ruaj khov zoo tshaj plaws thiab lub hauv paus ntsiab lus ntawm "qhov chaw ruaj khov siab."

Qhov chaw ua haujlwm raug rau cov txheej txheem lapping ultra-precision, ua tiav qhov roughness qis heev (feem ntau Ra ≤ 0.025 μm) thiab qhov tseeb ntawm qhov tiaj tiaj txog Qib 0 (≤ 3 μm / 1000 mm). Qhov no muab lub dav hlau siv tsis hloov pauv, tsis hloov pauv.

Thaum lub sijhawm tshuaj xyuas, cov khoom sib xyaw raug muab tso rau ntawm qhov chaw no. Cov cuab yeej xws li cov ntsuas ntsuas lossis cov ntsuas lever raug siv los ntsuas qhov sib txawv me me ntawm cov khoom thiab lub phaj. Cov txheej txheem no tso cai rau cov engineers kom paub tseeb tias qhov tiaj tiaj thiab sib luag ntawm cov khoom, lossis siv lub phaj ua lub datum ruaj khov los xyuas cov yam ntxwv tseem ceeb xws li qhov sib nrug ntawm qhov thiab qhov siab ntawm cov kauj ruam. Qhov tseem ceeb, lub granite lub zog siab (Elastic Modulus ntawm 80-90 GPa) ua kom ntseeg tau tias lub phaj nws tus kheej tsis deflect lossis deform nyob rau hauv qhov hnyav ntawm cov khoom hnyav, lav qhov kev ncaj ncees ntawm cov ntaub ntawv tshuaj xyuas.

Kev Tsim Kho rau Kev Tshuaj Xyuas: Kev Tsim Qauv thiab Kev Zoo Tshaj Plaws ntawm Cov Khoom Siv

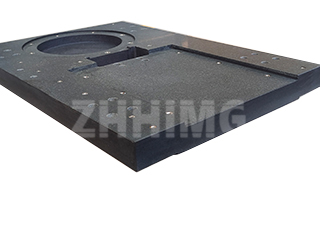

ZHHIMG® Cov Phaj Tshuaj Xyuas tau tsim los nrog kev tsom mus rau kev hloov pauv tau yooj yim thiab kev ua tib zoo saib xyuas:

- Kev Hloov Kho Kom Haum: Tshaj li qhov chaw tiaj tiaj ntawm lub plawv, ntau tus qauv muaj cov qhov sib xyaw ua ke lossis V-grooves. Cov no yog qhov tseem ceeb rau kev kho kom ruaj ntseg cov khoom nyuaj lossis cov khoom tsis sib xws, xws li cov ncej thiab cov khoom zoo li lub disk, tiv thaiv kev txav mus los thaum lub sijhawm ntsuas rhiab heev.

- Kev Nyab Xeeb thiab Kev Siv Tau: Cov npoo tiav nrog lub chamfer mos mos, puag ncig los txhim kho kev nyab xeeb ntawm tus neeg teb xov tooj thiab tiv thaiv kev raug mob tsis txhob txwm.

- Lub Txheej Txheem Qib: Lub hauv paus phaj muaj cov ceg txhawb nqa uas hloov kho tau (zoo li cov ntsia hlau qib), uas tso cai rau tus neeg siv kho lub phaj kom raug me ntsis kom haum rau kab rov tav (≤0.02mm/m qhov tseeb).

- Cov Khoom Siv Zoo: Peb tsuas yog siv cov granite zoo tshaj plaws, tsis muaj qhov thiab tawg, uas dhau los ntawm cov txheej txheem laus ntuj tsim 2-txog-3-xyoo. Cov txheej txheem ntev no tshem tawm kev ntxhov siab sab hauv cov khoom, lav qhov ruaj khov mus sij hawm ntev thiab lub sijhawm khaws cia qhov tseeb tshaj tsib xyoos.

Qhov twg Precision tsis sib tham tau: Cov Cheeb Tsam Tseem Ceeb

Lub Phaj Tshuaj Xyuas Granite yog qhov tseem ceeb uas qhov kev ua haujlwm siab ncaj qha cuam tshuam rau kev nyab xeeb thiab kev ua tau zoo:

- Kev Lag Luam Tsheb: Qhov tseem ceeb rau kev txheeb xyuas qhov tiaj tiaj ntawm cov thaiv cav thiab cov plhaub kis tau tus mob kom ntseeg tau tias muaj kev sib khi zoo meej.

- Kev Lag Luam Aerospace: Siv rau kev txheeb xyuas qhov loj me ntawm cov hniav turbine thiab cov khoom siv tsaws, qhov twg qhov kev hloov pauv cuam tshuam rau kev nyab xeeb ntawm kev ya dav hlau.

- Kev Ua Pwm thiab Tuag: Txheeb xyuas qhov tseeb ntawm qhov chaw ntawm cov pwm thiab cov cores, ncaj qha txhim kho qhov zoo ntawm qhov kawg cam khwb cia lossis cov khoom tsim.

- Electronics & Semiconductor: Tseem ceeb heev rau kev tshuaj xyuas kev sib dhos ntawm cov khoom siv rau cov khoom siv semiconductor uas muaj zog ntau, qhov twg kev sib dhos ntawm qib micron yog qhov yuav tsum tau ua kom raug.

Kev Tiv Thaiv Koj Cov Ntaub Ntawv: Cov Kev Xyaum Zoo Tshaj Plaws rau Kev Txij Nkawm

Yuav kom khaws tau qhov tseeb ntawm koj lub Phaj Tshuaj Xyuas hauv qab micron, yuav tsum ua raws li cov txheej txheem kev saib xyuas nruj heev:

- Yuav tsum tau ua kom huv si: Tom qab kuaj xyuas tas, siv txhuam mos mos los ntxuav tag nrho cov seem seem (tshwj xeeb yog cov hlau tawg) ntawm qhov chaw.

- Ceeb Toom Txog Kev Xeb: Txwv tsis pub muab cov kua qaub (acids lossis alkalis) tso rau ntawm qhov chaw granite, vim tias lawv tuaj yeem ua rau lub pob zeb puas mus tas li.

- Kev Txheeb Xyuas Tsis Tu Ncua: Yuav tsum tau txheeb xyuas qhov tseeb ntawm lub phaj tsis tu ncua. Peb xav kom koj siv cov cuab yeej ntsuas qhov tiaj tiaj uas tau ntawv pov thawj txhua rau lub hlis.

- Kev Tuav: Thaum txav lub phaj, tsuas yog siv cov cuab yeej tsa tshwj xeeb xwb thiab tsis txhob tig lossis ua rau lub phaj raug cuam tshuam tam sim ntawd, uas tuaj yeem ua rau nws ruaj khov mus sij hawm ntev.

Los ntawm kev kho Granite Inspection Plate ua lub cuab yeej ntsuas siab, cov tuam txhab tsim khoom tuaj yeem ua kom ntseeg tau tias muaj kev txheeb xyuas qhov ntev ntawm ntau xyoo, txhawb nqa qhov zoo thiab kev nyab xeeb ntawm lawv cov khoom nyuaj tshaj plaws.

Lub sijhawm tshaj tawm: Kaum Ib Hlis-05-2025