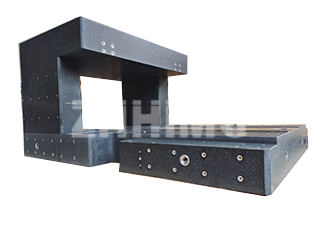

Hauv kev tsim khoom thiab kev ntsuas qhov tseeb siab, lub pob zeb granite yog lub hauv paus tsis muaj kev sib cav - qhov kev siv xoom rau kev ntsuas qhov ntev. Nws lub peev xwm los tuav lub dav hlau ze li zoo meej tsis yog tsuas yog ib qho cwj pwm ntuj tsim xwb, tab sis yog qhov tshwm sim ntawm cov txheej txheem tswj hwm zoo, ua raws li kev saib xyuas tsis tu ncua. Tab sis txoj kev taug kev kawg uas lub pob zeb granite siv los ua kom tiav qhov zoo tagnrho yog dab tsi, thiab cov txheej txheem twg tsim nyog los txhawb nws? Rau cov engineers thiab cov thawj tswj xyuas zoo, kev nkag siab txog ob qho tib si keeb kwm ntawm qhov kev ua kom raug no thiab cov kauj ruam tsim nyog los khaws cia nws yog qhov tseem ceeb rau kev tswj hwm qhov zoo ntawm kev tsim khoom.

Ntu 1: Cov Txheej Txheem Ua Duab - Kev Tsim Kho Kom Tiaj

Kev taug kev ntawm cov pob zeb granite, los ntawm cov pob zeb txiav ntxhib mus rau cov phaj nto qib siv, muaj ntau theem ntawm kev sib tsoo, kev ruaj khov, thiab kev ua tiav, txhua theem tsim los txo qhov yuam kev ntawm qhov ntev.

Thaum xub thawj, tom qab txiav, lub slab yuav raug rau Rough Shaping thiab Grinding. Theem no tshem tawm ntau yam khoom siv los tsim kom muaj qhov geometry kawg thiab qhov tiaj tiaj. Qhov tseem ceeb, cov txheej txheem no kuj ua haujlwm los tso tawm ntau qhov kev ntxhov siab uas tsim nyob rau hauv lub pob zeb thaum lub sijhawm quarrying thiab kev txiav thawj zaug. Los ntawm kev cia lub slab "kho" thiab rov ruaj khov tom qab txhua kauj ruam tshem tawm cov khoom tseem ceeb, peb tiv thaiv kev hloov pauv yav tom ntej, ua kom ruaj khov mus sij hawm ntev.

Qhov kev hloov pauv tiag tiag tshwm sim thaum lub sijhawm The Art of Precision Lapping. Lapping yog qhov txheej txheem kawg, tshwj xeeb heev uas ua kom lub ntsej muag semi-flat mus rau hauv lub dav hlau uas tau lees paub. Qhov no tsis yog kev sib tsoo tshuab; nws yog kev ua haujlwm ceev ceev, qis qis, thiab siab. Peb siv cov khoom sib xyaw ua ke zoo, xoob - feem ntau yog pob zeb diamond slurry - dai rau hauv cov kua nruab nrab, siv ntawm qhov chaw granite thiab lub phaj lapping hlau. Kev txav mus los raug tswj hwm kom ntseeg tau tias cov khoom siv sib npaug thoob plaws qhov chaw. Qhov nruab nrab no, rov ua dua manually thiab mechanically hauv cov kauj ruam rov ua dua, maj mam ua kom qhov tiaj tiaj mus rau hauv microns lossis txawm tias sub-microns (ua tau raws li cov qauv nruj xws li ASME B89.3.7 lossis ISO 8512). Qhov kev ua tiav ntawm no yog tsawg dua txog lub tshuab thiab ntau dua txog tus neeg teb xov tooj lub peev xwm, uas peb pom tias yog ib qho khoom siv tseem ceeb, tsis tuaj yeem hloov pauv tau.

Ntu 2: Kev Txij Nkawm—Tus yuam sij rau kev ua kom raug

Lub phaj granite yog ib qho cuab yeej ua haujlwm kom raug, tsis yog lub rooj ua haujlwm. Thaum tau ntawv pov thawj lawm, nws lub peev xwm los tswj qhov raug yog nyob ntawm cov txheej txheem ntawm tus neeg siv thiab ib puag ncig.

Kev Tswj Xyuas Ib Puag Ncig yog qhov tseem ceeb tshaj plaws uas cuam tshuam rau qhov tseeb ntawm granite. Txawm hais tias granite muaj qhov coefficient qis ntawm thermal expansion (COE), qhov sib txawv ntawm qhov kub thiab txias ntawm sab saum toj thiab hauv qab (qhov kub thiab txias ntsug) tuaj yeem ua rau tag nrho lub slab ua dome lossis warp. Yog li ntawd, lub phaj yuav tsum tau khaws cia kom deb ntawm tshav ntuj ncaj qha, cua txias, thiab cov cua sov ntau dhau. Ib puag ncig zoo tagnrho tswj tau qhov ruaj khov 68 ° F ± 1 ° F (20 ℃ ± 0.5 ℃).

Hais txog Kev Siv thiab Kev Ntxuav, kev siv tas li ntawm ib cheeb tsam ua rau muaj kev hnav tsis sib xws. Yuav kom daws tau qhov teeb meem no, peb xav kom koj tig lub slab ntawm nws lub rooj thiab faib cov kev ntsuas thoob plaws tag nrho qhov chaw. Kev ntxuav tas li yog qhov yuav tsum tau ua. Cov hmoov av thiab cov khib nyiab me me ua rau hnav sai dua. Tsuas yog siv cov tshuaj ntxuav granite tshwj xeeb, lossis cov cawv isopropyl uas muaj purity siab, xwb. Tsis txhob siv cov tshuaj ntxuav hauv tsev lossis cov tshuaj ntxuav dej uas tuaj yeem tso cov khoom seem nplaum lossis, yog tias siv dej, yuav txias thiab ua rau qhov chaw puas ib ntus. Thaum lub slab tsis ua haujlwm, nws yuav tsum tau npog nrog lub hau huv, mos, thiab tsis txhuam.

Thaum kawg, txog Kev Rov Kho Dua thiab Kev Rov Tsim Dua, txawm tias muaj kev saib xyuas zoo tag nrho, kev hnav yog qhov tsis zam. Nyob ntawm qib siv (piv txwv li, Qib AA, A, lossis B) thiab kev ua haujlwm, lub phaj granite nto yuav tsum tau rov kho dua txhua 6 txog 36 lub hlis. Tus kws tshaj lij uas tau ntawv pov thawj siv cov cuab yeej xws li autocollimators lossis laser interferometers los kos duab qhov sib txawv ntawm qhov chaw. Yog tias lub phaj poob sab nraum nws qib kev kam rau siab, ZHHIMG muab cov kev pabcuam rov ua dua tshiab. Cov txheej txheem no suav nrog kev coj lub voj voog precision rov qab los rau ntawm qhov chaw lossis rau peb lub chaw kom rov qab kho qhov tiaj tiaj qub, ua kom lub cuab yeej lub neej ntev dua.

Los ntawm kev nkag siab txog cov txheej txheem ua kom zoo thiab cog lus rau lub sijhawm saib xyuas zoo, cov neeg siv tuaj yeem ua kom lawv cov phaj granite tseem yog lub hauv paus ruaj khov rau txhua yam lawv xav tau zoo, kaum xyoo tom qab kaum xyoo.

Lub sijhawm tshaj tawm: Lub Kaum Hli-24-2025