Hauv kev tsim PCB (Printed Circuit Board), qhov tseeb ntawm qhov drilling txiav txim siab ncaj qha rau kev ua haujlwm hluav taws xob thiab cov txiaj ntsig ntawm lub rooj tsavxwm circuit. Txij li cov chips xov tooj ntawm tes mus rau aerospace circuit boards, qhov tseeb ntawm txhua qhov micron-level aperture yog qhov tseem ceeb rau kev vam meej lossis tsis ua tiav ntawm cov khoom. Granite bases, nrog lawv cov khoom siv tshwj xeeb thiab cov txiaj ntsig zoo ntawm cov qauv, tab tom dhau los ua "tus khub kub" ntawm PCB drilling khoom siv, tsav tsheb kev lag luam precision mus rau qhov siab tshiab.

I. Qhov Zoo Tshaj Plaws: Kev ua haujlwm ruaj khov tso lub hauv paus rau kev ua kom raug

Kev ruaj khov thermal zoo heev

Thaum lub sijhawm ua PCB drilling, lub cua sov uas tsim los ntawm kev tig ceev ceev ntawm lub laum tuaj yeem ncav cuag 60-80 ℃. Kev nthuav dav ntawm cov khoom siv hlau ib txwm vim yog cua sov tuaj yeem ua rau qhov chaw drilling hloov pauv yooj yim. Tus coefficient ntawm thermal expansion ntawm granite tsuas yog 4-8 × 10⁻⁶ / ℃, uas tsuas yog 1/5 ntawm cov hlau. Qhov no txhais tau tias txawm tias qhov kub thiab txias hloov pauv sai sai, qhov deformation ntawm lub hauv paus granite tuaj yeem tsis quav ntsej. Tom qab ib lub tuam txhab tsim khoom siv hluav taws xob tau txais lub hauv paus granite, qhov yuam kev ntawm qhov chaw drilling tau txo qis los ntawm ± 50μm mus rau ± 10μm, txhim kho qhov sib xws ntawm kev ua haujlwm hluav taws xob ntawm lub rooj tsavxwm circuit.

2. Kev ua tau zoo heev ntawm av qeeg

Qhov kev co siab ntawm lub tshuab drilling ntawm ntau txhiab lub revolutions ib feeb tuaj yeem cuam tshuam rau qhov ntsug ntawm lub laum ntsis, ua rau muaj qhov sib txawv ntawm lub qhov. Cov khoom siv damping ntuj hauv granite ua rau nws nqus tau ntau dua 90% ntawm cov khoom siv vibrations (20-50Hz). Cov ntaub ntawv ntsuas qhia tau tias tom qab txhim kho lub hauv paus granite, qhov kev co ntawm lub laum ntsis txo qis los ntawm 15μm mus rau 3μm, thiab tus nqi Ra ntawm qhov roughness ntawm phab ntsa qhov laum txo qis los ntawm 60%, txo cov burrs thiab delamination teeb meem ntawm phab ntsa qhov.

3. Kev tiv thaiv hnav ntev ntev

Kev khawb PCB yog ib qho kev ua haujlwm siab thiab muaj qhov yuav tsum tau ua kom lub hauv paus tsis yooj yim hnav. Granite muaj Mohs hardness ntawm 6 txog 7 thiab nws qhov kev hnav tsis yooj yim hnav yog peb npaug ntawm cov hlau ib txwm. Ib lub Hoobkas PCB loj tau siv cov hauv paus granite tas li rau peb xyoos. Qhov hnav ntawm qhov chaw tsawg dua 0.01 hli. Piv nrog cov hauv paus hlau, lub voj voog hloov pauv tau ntev dua ob zaug, ua rau txo cov nqi kho khoom siv.

II. Kev Txhim Kho Cov Txheej Txheem: Kev tsim qauv tshwj xeeb ua rau kev ua haujlwm zoo dua

Cov hauv paus granite niaj hnub no, los ntawm kev ua tiav thiab cov qauv tshiab, ua rau lawv cov nqi siv ntxiv:

Kev ua tiav ntawm cov duab tiaj tiaj: Los ntawm kev siv cov thev naus laus zis tswj kev sib txuas tsib-axis, qhov tiaj tiaj ntawm lub hauv paus raug tswj tsis pub dhau ± 0.5μm / m, muab qhov chaw siv rau cov khoom siv drilling thiab xyuas kom meej tias qhov yuam kev ntsug ntawm lub laum me ntsis tsawg dua 0.01 °.

Cov qauv nqus dej ntawm lub honeycomb: Tus qauv tsim sab hauv ntawm lub honeycomb tsim ib lub qhov ywj pheej, ua tiav ntau theem ntawm kev txo qis ntawm lub zog co, thiab tshwj xeeb tshaj yog tsim rau kev ua cov qhov me me ntawm 0.1 hli lossis tsawg dua.

Cov kav dej txias uas tau teeb tsa ua ntej: Rau cov khoom siv drilling muaj zog siab, lub kaw lus dej txias uas tau teeb tsa hauv micro-channel tau teeb tsa los tswj qhov sib txawv ntawm qhov kub ntawm qhov chaw hauv qab ± 0.5 ℃, tshem tawm tag nrho qhov kev pheej hmoo ntawm kev hloov pauv thermal.

Kev teeb tsa T-qhov chaw kho kom haum: Qhov sib nrug ntawm T-qhov chaw thiab qhov tseeb (± 0.01 hli) raug kho kom haum raws li tus qauv tshuab drilling kom ua tiav qhov chaw sai thiab kev teeb tsa ntawm cov khoom siv, txo lub sijhawm ua haujlwm ntawm ib lub cuab yeej los ntawm 70%.

Iii. Cov Pov Thawj Kev Lag Luam: Kev Txhim Kho Kev Ua Haujlwm Pom Tseeb

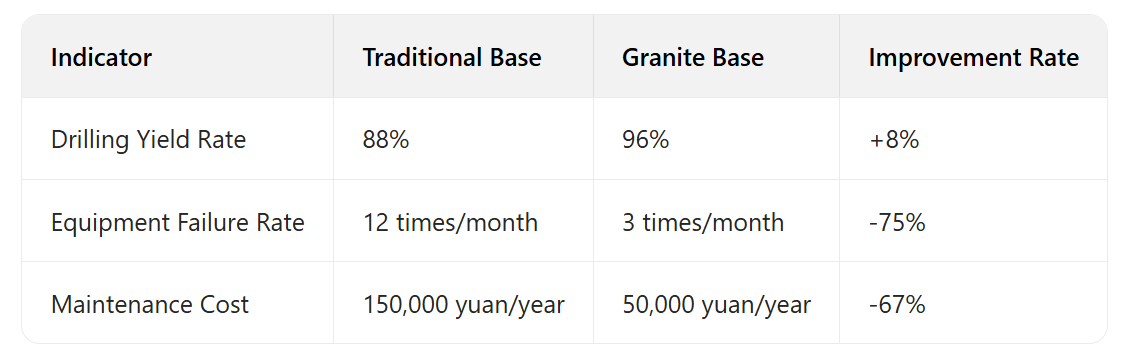

Tom qab ib lub tuam txhab tsim PCB ua ntej tau qhia txog cov hauv paus granite, nws cov ntaub ntawv tsim khoom tau ua tiav qhov kev txhim kho zoo kawg nkaus:

Qhov tseem ceeb tshaj, lub hauv paus granite tau pab cov tuam txhab lag luam hla dhau cov teeb meem kev siv tshuab, ua tiav kev txiav txim rau cov qhov me me ntawm 0.2 hli lossis tsawg dua, thiab qhib kev lag luam muaj nqis ntxiv.

Iv. Cov txiaj ntsig zoo rau kev ruaj khov: Kev xaiv zoo tshaj plaws rau kev tsim khoom ntsuab

Granite yog pob zeb ntuj tsis muaj tshuaj lom neeg thiab tsis muaj VOCs emissions, ua tau raws li RoHS cov qauv kev tiv thaiv ib puag ncig. Nws lub neej ua haujlwm ntev heev txo qhov zaus ntawm kev hloov khoom siv, txo cov khoom siv thiab cov pa roj carbon. Ib lub koom haum tiv thaiv ib puag ncig kev xam pom qhia tau hais tias kev siv lub hauv paus granite rau ib lub cuab yeej drilling PCB tuaj yeem txo cov pa roj carbon los ntawm 3 tons thoob plaws nws lub neej tag nrho, uas yog nyob rau hauv kab nrog kev hloov pauv ntsuab ntawm kev lag luam tsim khoom.

Txij li kev tswj hwm qhov tseeb ntawm micron mus rau kev ua kom zoo dua tag nrho cov txheej txheem, cov hauv paus granite tab tom hloov kho cov qauv ntawm cov txheej txheem drilling PCB nrog lawv cov txiaj ntsig kev ua tau zoo uas tsis tuaj yeem hloov pauv tau. Hauv lub caij nyoog tam sim no ntawm kev thov siab rau 5G thiab AI chips, kev xaiv lub hauv paus granite tsis yog tsuas yog kev nqis peev rau qhov zoo ntawm cov khoom tab sis kuj yog ib kauj ruam tseem ceeb los ntes thaj chaw siab ntawm thev naus laus zis.

Lub sijhawm tshaj tawm: Lub Rau Hli-17-2025