Hauv plawv ntawm kev tsim khoom siv tshuab thiab kev lag luam metrology muaj ib lub cuab yeej tseem ceeb: Lub Phaj Hlau Cast. Cov cuab yeej siv planar no yog qhov tseem ceeb rau kev tshuaj xyuas qhov workpiece kom raug, kev sau ntawv kom raug, thiab ua haujlwm ua cov qauv ruaj khov rau kev teeb tsa cov cuab yeej siv tshuab. Ntawm ZHHIMG®, peb txoj kev cog lus rau qhov tseeb tshaj plaws txuas ntxiv mus dhau peb cov khoom granite nto moo mus rau cov qauv nruj uas tswj hwm txhua yam cuab yeej metrology tseem ceeb. Kev nkag siab txog cov txheej txheem ua tib zoo - los ntawm kev casting mus rau kev teeb tsa - yog qhov tseem ceeb rau kev ua kom zoo thiab lub neej ntev ntawm cov khoom siv hauv pem teb tseem ceeb no.

Kev Tswj Xyuas Kev Ua Haujlwm: Cov Kev Ceev Faj hauv Kev Ua Hlau Casting

Kev tsim cov hlau cam khwb zoo pib nrog kev qhuab ntuas heev hauv lub chaw tsim khoom. Cov neeg ua haujlwm yuav tsum ua raws li cov txheej txheem tswj hwm uas tsom mus rau kev yooj yim thiab kev sib xws. Qhov no suav nrog kev tsim cov qauv uas txo cov naj npawb ntawm cov nplaim sib cais thiab cov xuab zeb thaum ua kom ntseeg tau tias cov ces kaum zoo tshaj plaws thiab hloov pauv cov phab ntsa kom du. Kev xaiv lub kaw lus gating tsim nyog yog qhov tseem ceeb; nws yuav tsum ua kom muaj kev sib law liag, ua rau muaj kev sib xyaw ua ke, kev ntxhov siab tsawg.

Qhov tseem ceeb, qhov zoo ntawm cov xuab zeb molding cuam tshuam ncaj qha rau qhov kawg casting. Cov xuab zeb sib tov yuav tsum muaj qhov permeability zoo heev, lub zog ntub dej, fluidity, plasticity, thiab collapsibility. Qhov no yog ua tiav los ntawm kev ua raws li cov txheej txheem pub mis khoom - xuab zeb qub, xuab zeb tshiab, av nplaum, hmoov thee, thiab dej - thiab tswj lub sijhawm sib tov kom meej ntawm rau txog xya feeb. Cov xuab zeb sib tov ces so thiab sieve kom txhim kho nws qhov permeability thiab fluidity ua ntej siv.

Cov txheej txheem nchuav nws tus kheej xav tau kev tsom mus rau qhov tsis txav. Cov hlau yaj yuav tsum tau txhaj tshuaj kom zoo thiab tshem tawm cov slag kom huv si ua ntej pib nchuav. Kev ntws tas mus li thiab ruaj khov yog qhov tseem ceeb kom tiv thaiv cov qhov tsis zoo xws li xuab zeb yaig thiab tsim cov qhov xuab zeb. Kev teb sai sai rau txhua qhov xau yog qhov tsim nyog kom tsis txhob muaj qhov tsis zoo loj xws li kaw txias thiab nchuav tsis tiav. Thaum kawg, cov txheej txheem ntxuav kom huv si ua kom ntseeg tau tias qhov casting txias raug tshem tawm ntawm pwm yam tsis muaj kev puas tsuaj, ua rau qhov chaw tsis muaj qhov tsis zoo thawj zaug.

Tsim, Qhov Tsis Zoo, thiab Qhov Ceev: Kev Xyuas Kom Muaj Kev Ruaj Ntseg ntawm Cov Qauv

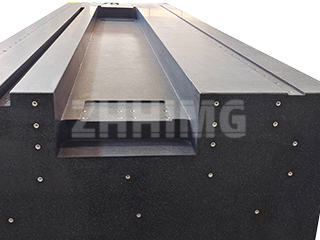

Lub platform hlau cam khwb zoo yog tsim los kom ruaj khov. Feem ntau tsim los ua ib sab lossis lub thawv, lawv cov chaw ua haujlwm feem ntau yog plaub fab lossis plaub fab. Kev ruaj khov ntawm cov qauv yog nyob ntawm cov yam ntxwv xws li phab ntsa thiab cov tav txhawb nqa, uas yuav tsum tau ntsuas raws li qhov muaj peev xwm thauj khoom thiab qib kev ua tau zoo. Qhov siab ntawm cov tav txhawb nqa no - txawm tias ib nrab tav, tag nrho tav, lossis tiaj tiaj - muab qhov nro thiab kev txhawb nqa tsim nyog.

Txawm tias muaj kev tswj hwm casting nruj tshaj plaws los xij, qhov tsis zoo me me kuj yuav tshwm sim. Rau cov platforms qis dua qhov tseeb Qib "0," cov qauv kev lag luam tso cai rau kev kho qhov txhaws ntawm cov qhov xuab zeb me me (txoj kab uas hla tsawg dua 14 hli) siv cov khoom siv tib yam, yog tias cov khoom kho qhov nyuaj qis dua cov hlau nyob ib puag ncig. Txawm li cas los xij, qhov chaw ua haujlwm yuav tsum tsis muaj qhov tsis zoo loj, suav nrog cov kab nrib pleb, porosity, slag inclusions, thiab shrinkage cavities, thiab qhov chaw casting yuav tsum du nrog cov xim nplaum ruaj khov. Kev xaiv lub platform uas tau dhau los ntawm kev laus ntuj lossis kev kho cua sov dag yog qhov tseem ceeb, vim tias cov txheej txheem no txo kev ntxhov siab sab hauv thiab tiv thaiv kev hloov pauv diagonal yav tom ntej.

Kev Teeb Tsa thiab Kev Txij Nkawm: Khaws Cia Kev Ntsuas Tseeb

Lub platform hlau cam khwb cia, txawm tias nws zoo li cas los xij, tsuas yog qhov tseeb raws li nws qhov kev teeb tsa. Nws yuav tsum tau teeb tsa kab rov tav nrog lub nra hnyav faib sib npaug thoob plaws txhua qhov chaw txhawb nqa, feem ntau ua tiav los ntawm kev siv cov ceg kho tau ntawm lub bracket txhawb nqa. Cov txheej txheem teeb tsa no, coj los ntawm qib hluav taws xob siab lossis qib thav duab, yog qhov tseem ceeb rau kev ua tiav nws qhov tseeb ntsuas.

Yuav kom ua tau raws li qhov tseeb, qhov chaw ib puag ncig yog qhov tseem ceeb. Qhov kub ua haujlwm yuav tsum tswj tau nyob ib puag ncig 20 ℃ (± 5 ℃), thiab yuav tsum tsis txhob muaj kev co. Ua ntej pib ua haujlwm, qhov chaw yuav tsum tau ntxuav kom huv si kom tshem tawm cov xuab zeb seem, burrs, roj, thiab xeb, vim tias txawm tias cov khoom me me ua rau qhov tseeb tsis raug. Qhov chaw zoo me me, lossis du, yog qhov tseem ceeb rau lub neej ntev.

Yog siv kom raug thiab khaws cia kom zoo—tsis txhob nyob hauv qhov chaw noo, xeb, lossis kub heev—qhov chaw ua haujlwm ntawm lub platform hlau cam khwb cia tuaj yeem tswj tau ob lossis ntau xyoo. Lub platform nws tus kheej tuaj yeem kav ntev li ntau xyoo. Yog tias qhov kev ntsuas poob qis, nws tuaj yeem rov qab kho tau tag nrho los ntawm kev kho kom zoo lossis rov ua dua tshiab (scraping). Kev tshuaj xyuas tsis tu ncua raws li nws tus qauv calibration yog qhov yuav tsum tau ua, vim tias kev siv lub phaj tsis zoo yuav ua rau muaj kev hloov pauv ntawm kev ntsuas thiab cuam tshuam rau qhov zoo ntawm cov khoom kawg.

Ua ib lub cuab yeej tseem ceeb hauv kev lag luam tsheb, aerospace, instrument, thiab cov tshuab hnyav, lub platform hlau cam khwb cia yog ib qho pov thawj rau qhov tseeb tias kev ua haujlwm raug tsim los ntawm hauv av.

Lub sijhawm tshaj tawm: Lub Kaum Hli-31-2025